Page History

...

- only allowed to be used for electrical specialist for the used electrical voltage and power conditions

- only allowed to be used under electrical laboratory conditions

- only allowed to be used in horizontal position on a non-conducting and non-inflammable surface

- only allowed to be used with a wiring, which fulfills the current rating for the maximum possible currents.

- only allowed to be used with a suitable current limiting circuit

- The maximum continuous current must not exceed 30A.

- The delivered fuse "Littelfuse Tpye 142.5631.5302" must be used as current limiter between connector J5 and J6.

- To limit the current for smaller motor loads an ADDITIONALLY appropriate current limiter can be used e.g. a current limited power source or a fuse integrated in the wiring.

- only allowed to be used with appropriate connectors at the M5 screw connectors, which means M5 cable lugs must be used and fastened according to technical standards.

- only allowed to be used, if the "Drive Boad high current signals" conducting up to 30A nominal, are covered by isolating, mechanically stable, non-inflammable (UL V-1 or better) material

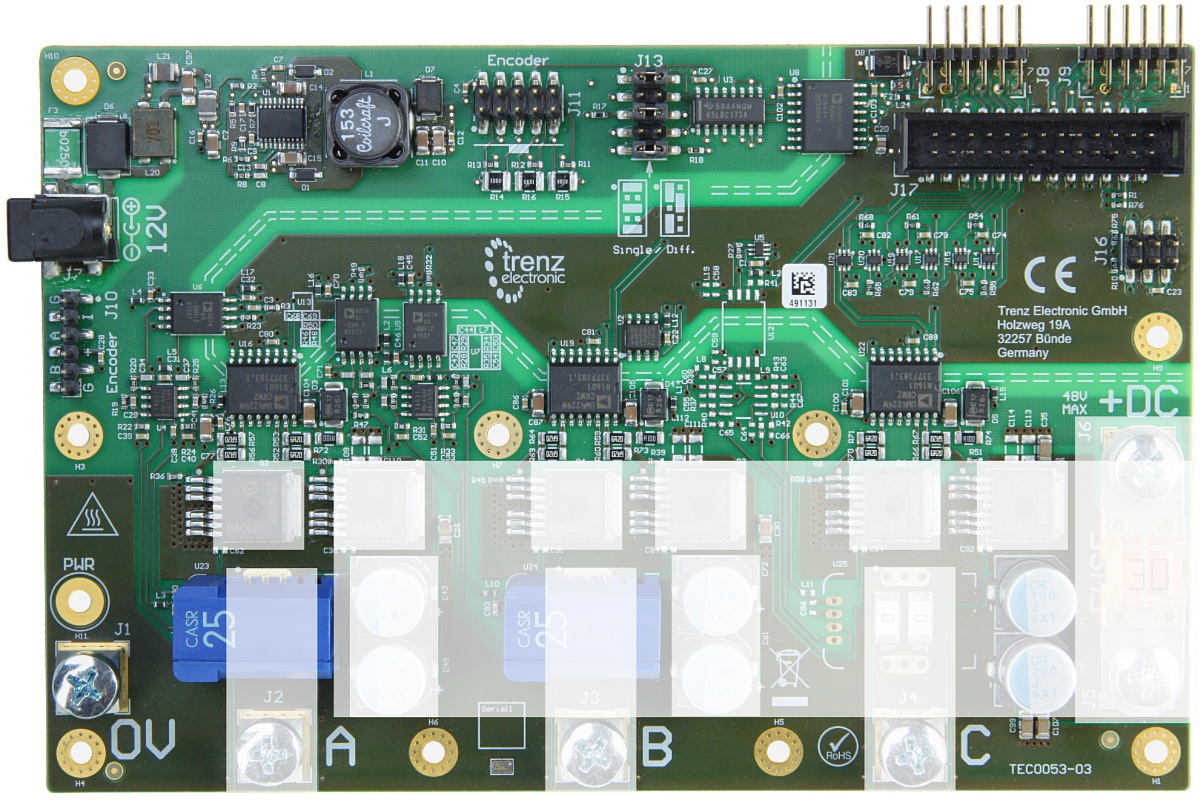

The "Drive Board high current signals" are the motor outputs A, B, C and Fuse F1 Connectors J5 an J6 and further internal connections shown white marked in the following picture:

Figure 5.

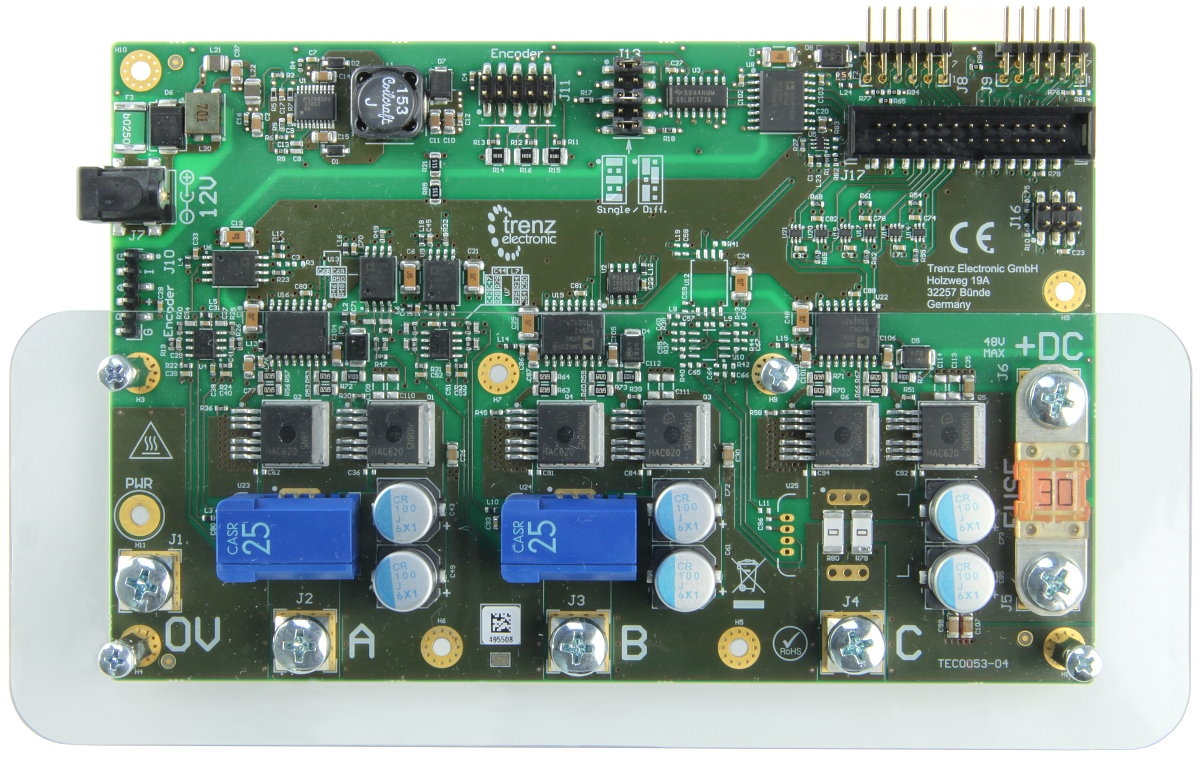

It is mandatory to use the delivered isolating cover of the PCB made of plexiglass as a minimum protection. Use holes H1, H9, H3 and H4 with the delivered 10mm spacers when mounting.

Figure 6: Top view of the Board with isolating transparent plexiglass cover

...

.

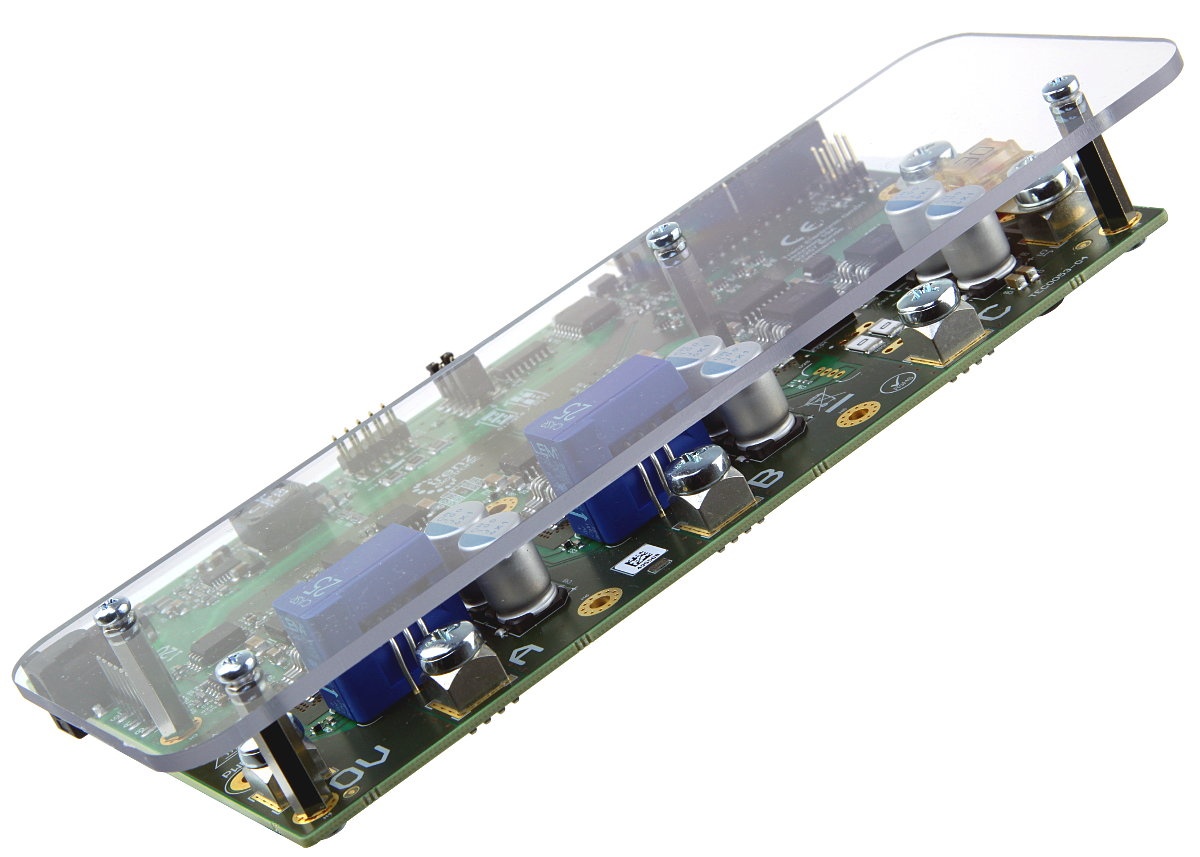

Figure 7: Side view of the Board with isolating

...

plexiglass cover.

The

...

cable lugs

...

used should be isolated in

...

the outer border area of the Drive Board.

...

Make sure that the

...

Isolating PCB Cover

...

is overlapping the conducting material by a minimum of 20 mm.

Initial operation

To use a separate power supply for the motor supply perform the following steps:

- Disconnect the reference motor board TEC0060 by unmounting its screws and the encoder cable from J10.

- Mount the delivered 30A fuse to the connectors J5 and J6 with the delivered M5 screws.

- For lower supply current requirements , caused by the power rating of the used motor , a fuse with a suitable lower and suitable current rating integrated in the supply wiring is recommended.

- Connect with cable lugs the DC of +DC 5..48V to J6 and the corresponding GND to J1.

- The cable length is limited to 3m.

- Connect the three motor phases to J2 (A), J3 (B) and J4 (C).

- The cable length is limited to 3m.

- Optional: connect the encoder to J10 or J11 and set jumper field according to signal specification: differential or single ended. See section TODO for details.

...

- +3V3 Supply from the Control Board, generated by Control Board supply

- +12V and

- optional Optional +5..48V Motor Supply

Reference Motor Board TEC0060

For easy connection of the reference Motor and Encoder to the Driver board a special Motor Adapter Board TEC0060 is included in the EDDP Kit.

Figure 8: Reference Motor Board TEC0060 with the Motor attached.

Reference Motor

The reference motor is manufactured by Anaheim Automation. The order code for the motor with the encoder already mounted is BLWR111D-24V-10000-1000SI. Please note that the encoder is not available separately. The nominal motor voltage is DC 24V, however, only 12V is supplied by the Reference Motor Board, which results in reduced performance.

The datasheet for the motor can be found at

http://www.anaheimautomation.com/manuals/brushless/L010234%20-%20BLWR11%20Series%20Product%20Sheet.pdf

The datasheet for the encoder can be found at

http://www.anaheimautomation.com/manuals/accessories/L010390%20-%20Single%20Ended%20Encoder%20with%20Index%20Channel.pdfRefer to the BLWR11 - Brushless DC Motors and Single-Ended Encoder with Index Channel for more information.

Technical Specifications

Absolute Maximum Ratings

| Parameter | Min | Max | Units | Notes |

|---|---|---|---|---|

DC +12V supply | 0 | 15 | V | |

| DC +5..48V supply | 0 | 50V | V | |

| DC +3V3 supply | -0.5 | 6 | V | |

| PWM Input | -0.5 | 6 | V | |

| ADC Digital Input | -0.5 | 3.8 | V | DC +3V3 = 3.3V |

| Encoder Input | -10 | 15 | V |

Table 3: Absolute maximum ratings.

Recommended Operating Conditions

| Parameter | Min | Max | Units | Notes |

|---|---|---|---|---|

DC +12V supply | 11.5 | 12.5 | V | |

| DC +5..48V supply | 5 | 48 | V | |

| DC +3V3 supply | 3.0 | 3.6 | V | |

| PWM Input | 0 | DC +3V3 supply | V | |

| ADC Digital Input | 0 | DC +3V3 supply | V | |

| Encoder Input | -7 | 12 | V |

Table 4: Recommended oprating conditions.

Electrical characteristics

...

| Parameter | Min | Max | Units | Notes |

|---|---|---|---|---|

| PWM Input Logic High Level | 2.2 | V | ||

| PWM Input Logic Low Level | 0.8 | V | ||

| ADC Digital Input Logic High Level | 2.7 | V | ||

| ADC Digital Input Logic Low Level | 0.6 | V | ||

| ADC Digital Output Logic High Level | 3.2 | 3.3 | V | Io=-200μA |

| ADC Digital Output Logic Low Level | 0 | 0.4 | V | Io=+200μA |

| Encoder Input Logic High Level (Differential) | -0.2 | V | ||

| Encoder Input Logic Low Level (Differential) | -0.01 | V | ||

| Encoder Input Logic High Level (Single Ended) | 2 | V | ||

| Encoder Input Logic Low Level (Single Ended) | 0.6 | V |

Table 5: Electrical characteristics.

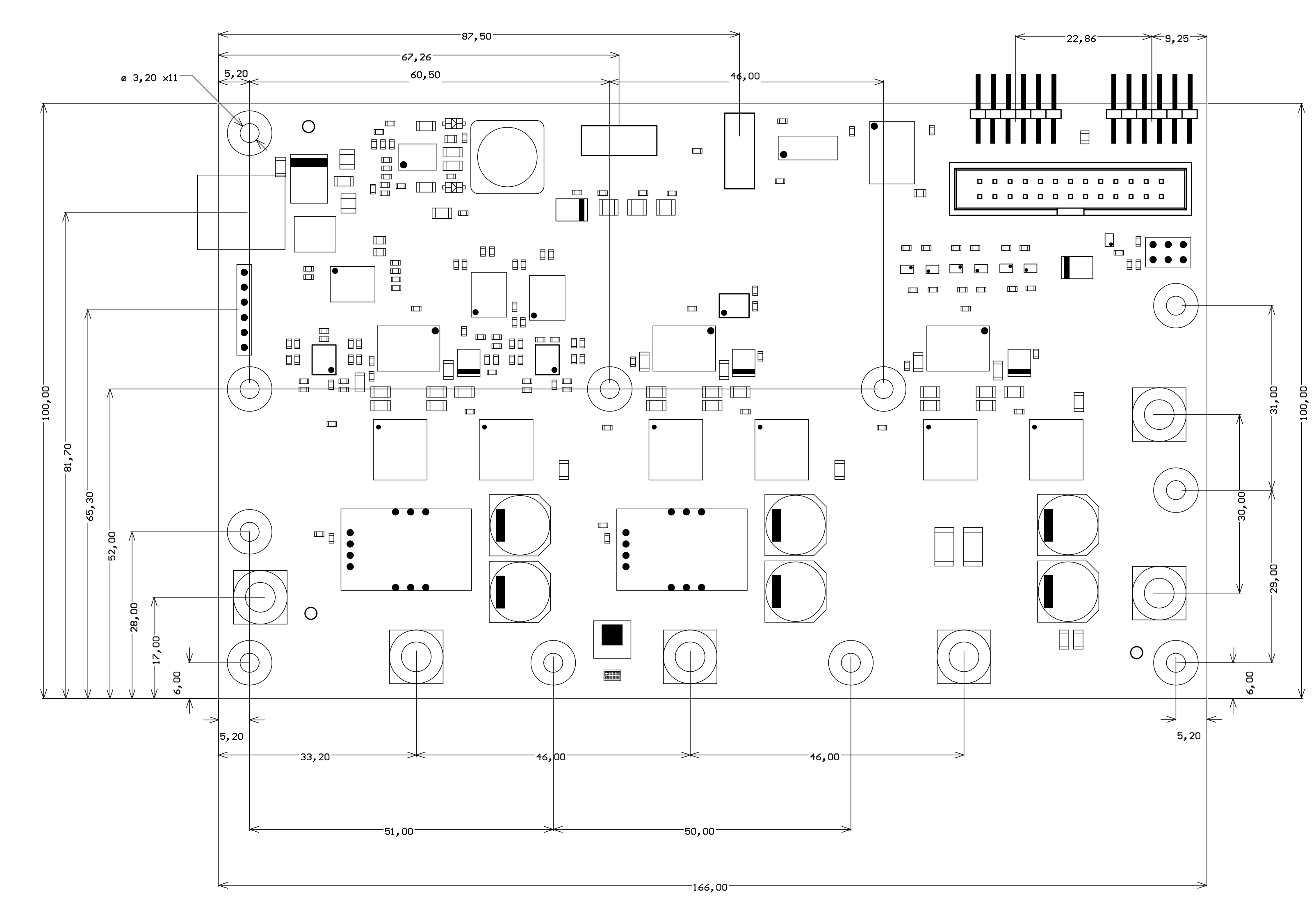

Physical Dimensions

Board size: 100 mm × 166 mm. Please download the assembly diagram for exact numbers.

PCB thickness: 1.75 mm +/-10%

Highest part on PCB: approximately 17 mm. Please download the step model for exact numbers.

All dimensions are shown in mmmillimeters. Additional sketches, drawings and schematics can be found TODO: here.

Figure 9: Physical Dimensions of the TEC0060 board.

Operating Temperature Ranges

0°C - 70°C, cooling might be required , depending on environment and airflow.

...

| Date | Revision | Notes | PCN Link | Documentation Link |

|---|---|---|---|---|

| 2017-08-14 | 04 | Initial public revision |

Table 6: Hardware revision history.

Hardware revision number is printed on the PCB board in the bottom right corner.

...

Date | Revision | Authors | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan Kumann | General formatting changes and small corrections. | |||||||||

| 2017-ß8-14 | v.10 | Antti Lukats, Andrei Errapart | Initial version. |

Table 7: Document change history.

Include Page EDPS Disclaimers EDPS Disclaimers