Table of Contents

Download PDF Version of this Document. |

Table of Contents |

Refer to https://shop.trenz-electronic.de/de/Download/?path=Trenz_Electronic/TE0711 for online version of this manual and the rest of available documentation. |

Trenz Electronic TE0711 is an industrial-grade FPGA module integrating a Xilinx Artix-7 FPGA, 32 MByte Quad SPI Flash memory for configuration and operation and powerful switching-mode power supplies for all on-board voltages. Numerous configurable I/O's are provided via rugged high-speed strips. All this on a tiny footprint, smaller than a credit card size at very competitive price. All Trenz Electronic SoM's in 4 x 5 cm form factor follow the same mechanical design rules, thus they are interchangeable.

Figure 1: TE0711-01 block diagram.

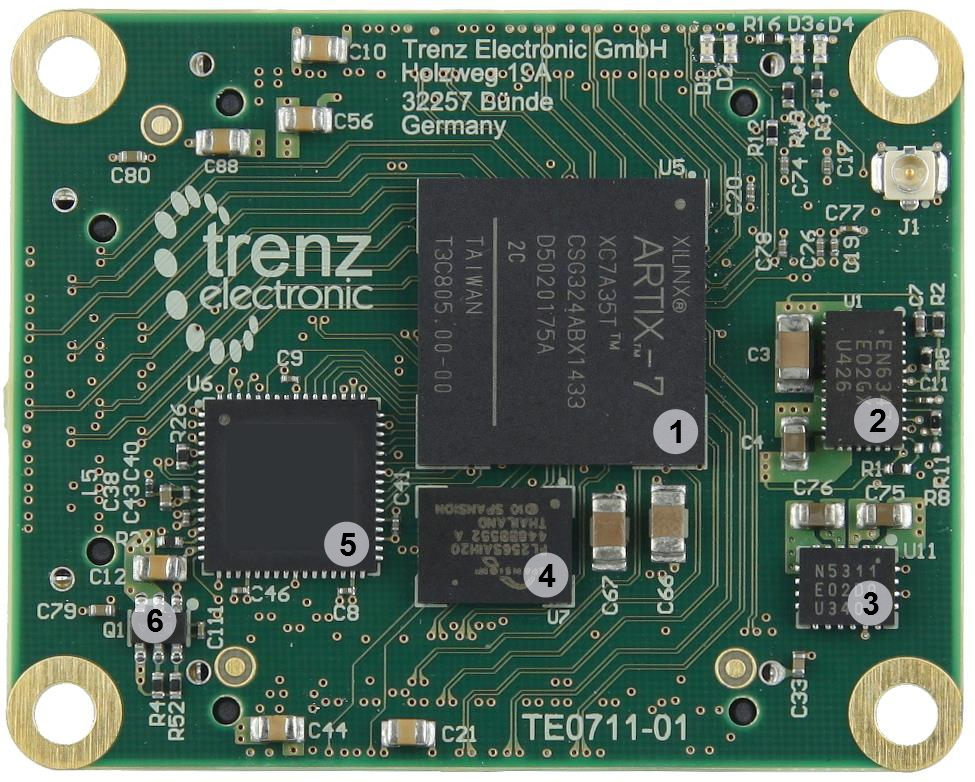

Figure 2: TE0711 (REV 01).

Industrial-grade Xilinx Artix-7 (15T to 100T) SoM (System on Module), supported by the free Xilinx Vivado WebPACK tool

Rugged for shock and high vibration

32 MByte QSPI Flash memory (with XiP support)

100 MHz MEMS oscillator

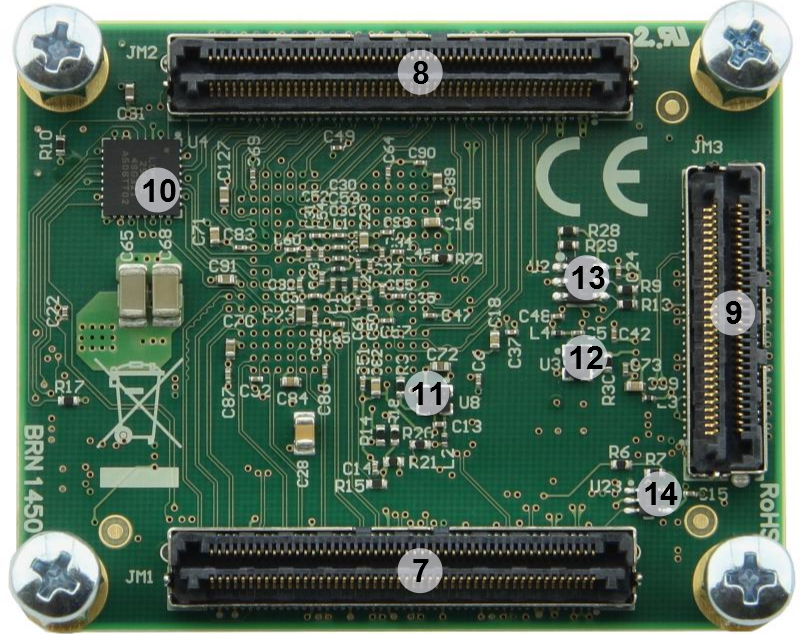

Plug-on module with 2 × 100-pin and 1 × 60-pin high-speed hermaphroditic strips

178 FPGA I/Os (84 differential pairs) are available on board-to-board connectors

On-board high-efficiency DC-DC converters

4.0 A x 1.0 V power rail

1.0 A x 1.8 V power rail

1.0 A x 1.5 V power rail

System management and power sequencing

eFUSE bit-stream encryption

AES bit-stream encryption

User LED

Evenly-spread supply pins for good signal integrity

Assembly options for cost or performance optimization available upon request.

| Storage Component | Content | Notes |

|---|---|---|

SPI Flash OTP Area | Empty, not programmed | Except serial number programmed by flash vendor. |

SPI Flash Quad Enable bit | Programmed | - |

SPI Flash main array | Demo design | - |

EFUSE USER | Not programmed | - |

EFUSE Security | Not programmed | - |

Table 1: Initial delivery state

I/O signals connected to the FPGA's I/O banks and B2B connector:

| Bank | Type | B2B Connector | I/O Signal Count | Voltage | Notes |

|---|---|---|---|---|---|

0 | HR | - | - | 3.3V | Configuration bank |

14 | HR | JM1 JM2 | 8 I/O pins 18 I/O pins, (9 LVDS pairs possible) | 3.3V | HR banks support voltages from 1.2V to 3.3V. See Xilinx Artix-7 datasheet (DS181) for voltage ranges. |

15 | HR | JM1 | 48 I/O pins 24 LVDS pairs possible | User | As above. |

16 | HR | JM1 | 6 I/O pins 3 LVDS pairs possible | 1.8V | As above. |

| 34 | HR | JM1 JM3 | 48 I/O pins 24 LVDS pairs possible | User | As above. |

| 35 | HR | JM2 | 50 I/O pins 24 LVDS pairs possible | User | As above. |

Table 2: Voltage ranges and pin-outs of available logic banks of the FPGA.

Please use Master Pin-out Table as primary reference for the pin mapping information.

JTAG access to the Xilinx Artix-7 and to the System Controller CPLD is provided through B2B connector JM2.

| JTAG Signal | B2B Connector |

|---|---|

| TCK | JM2-99 |

| TDI | JM2-95 |

| TDO | JM2-97 |

| TMS | JM2-93 |

Table 3: Pin-mapping of JTAG Interface on B2B connector

JTAGSEL pin on B2B connector JM1 is used to control which physical device is accessible via JTAG interface. If this pin is set to low or left open, JTAG interface is enabled for Xilinx Artix-7 FPGA, if set to high, JTAG interface for System Controller CPLD will be enabled. The use of Xilinx legacy development tools (ISE, iMPACT) is not recommended. iMPACT does not recognize any Xilinx Artix-7 below A100T model. |

Special purpose pins are connected to smaller System Controller CPLD and have following default configuration:

| Pin Name | Mode | Function | Default Configuration | B2B Connector |

|---|---|---|---|---|

| STAT_SC2 | Output | Power Good | Active high when all on-module power supplies are working properly. | JM1-30 |

| NRST_SC0 | Input | Reset | Active low reset signal, drive low to keep the system in reset (FPGA pin PROG_B will be driven by CPLD) | JM2-18 |

| JTAGSEL | Input | JTAG Select | Low for normal operation, high (3.3V) to programm the System Controller CPLD | JM1-89 |

| EN_SC3 | Input | Enable FPGA Core Voltage supply | High (3.3V) or open for normal operation, low to stop power-on sequencing | JM1-28 |

Table 4: Pin-description of System Controller CPLD

On the SoM TE0710 there is a total of 3 LEDS available. Two LEDs are status LEDs, one can freely used in costumer designs. The user LED is routed to the FPGA by the net with the schematic-name 'USERLED'.

When the FPGA is not configured the status LEDs will flash continuously. Finally once FPGA configuration has completed the status LEDs can be used in the user's FPGA design.

| LED | Color | Connected to pin | Description and Notes |

|---|---|---|---|

| D1 | red | SYSLED2 | User LED, active HIGH, connected to FPGA Pin A8 |

| D2 | green | SYSLED4 | User LED, active HIGH, connected to FPGA Pin R17 |

| D3 | green | SYSLED3 | User LED, active LOW, connected to FPGA Pin L15 |

| D4 | green | SYSLED1 | System Controller status LED, connected to CPLD |

Table 5: Description of the on board LEDs

The TE0710 is equipped with two MEMS oscillators to provide clock signals for two on-board Ethernet PHY's and DDR3 SDRAM.

| Clock | Frequency | IC | Connected to | Notes |

|---|---|---|---|---|

Reference oscillator clock for USB to UART/FIFO Bridge (FT2232H) | 12 MHz | U9 SiT8008AI-73-XXS-12.000000E | IC U6, FTDI FT2232H | - |

| FPGA bank 14 reference clock input | 100 MHz | U8 SiT8008AI-73-XXS-100.000000E | FPGA bank 14, pin P17 | reference clock for general user purposes |

Table 6: Clocks overview

An SPI flash memory S25FL256S (U7) is provided for FPGA configuration file storage. After configuration completes the remaining free memory can be used for application data storage. All four SPI data lines are connected to the FPGA allowing x1, x2 or x4 data bus widths to be used. The maximum data rate will be dependent on the bus width and clock frequency.

SPI Flash QE (Quad Enable) bit must be set, or the FPGA would not configure from Flash. This bit is always set at manufacturing. |

The system controller is used to coordinate the configuration of the FPGA. The FPGA is held in reset (by driving the PROG_B signal) until the power supplies have sequenced. Low level at NRST_SC0 pin also resets the FPGA. This signal can be driven from the user’s PCB via the B2B connector pin JM2-18. Input EN_SC3 is also gated to FPGA Reset and should be open or pulled up for normal operation. EN_SC3 low turns off on board DC-DC converters and stops power-on sequencing.

It is possible for the user to create their own system controller design using the Lattice Diamond software. Once created the design can be programmed into the device using the JTAG pins. The signal JTAGSEL should be set to 3.3V to enable programming mode. For normal operation it should be set to 0V.

There are one status LED connected to the system controller CPLD. When the FPGA is not configured the LED will flash continuously. Finally once FPGA configuration has completed the LEDs can be used in the user's FPGA design.

The TE0711-01 SoM has on-board USB 2.0 High Speed to UART/FIFO IC FT2232HQ from FTDI. Channel A can only be used in simple UART mode, Channel B can be used as UART, in FT245 FIFO mode, JTAG (MPSSE) or High Speed Serial modes.

All FT2232HQ-pins are connected to bank 14 with fixed 3.3V VCCIO and should be used with LVCMOS33 I/O Standard.

There is also a standard 256 Byte EEPROM connected to the FT2232HQ-chip available to store custom configuration settings. EEPROM settings can be changed using FTDI provided tools that can be downloaded from FTDI website. See FTDI website for more information.

Power supply with minimum current capability of 2A for system startup is recommended.

| Power Input Pin | Voltage Range | Max Current |

|---|---|---|

| VIN | 3.3V to 5.5V | Typical 200mA, depending on customer design and connections. |

| 3.3VIN | 3.3V | Typical 50mA, depending on customer design and connections. |

Table 7: maximal current of power supplies

Vin and Vin 3.3V can be connected to the same source (3.3 V). |

Lowest power consumption is achieved when powering the module from single 3.3V supply. When using split 3.3V/5V supplies the power consumption (and heat dissipation) will rise, this is due to the DC/DC converter efficiency (it decreases when VIN/VOUT ratio rises).

For highest efficiency of on board DC/DC regulators, it is recommended to use same 3.3V power source for both VIN and 3.3VIN power rails. Although VIN and 3.3VIN can be powered up in any order, it is recommended to power them up simultaneously.

It is important that all baseboard I/O's are 3-stated at power-on until System Controller sets STAT_SC2 signal high (B2B connector JM1, pin 30), or 3.3V is present on B2B connector JM2 pins 10,12 or 91, meaning that all on-module voltages have become stable and module is properly powered up.

See Xilinx datasheet DS181 (for Artix7) for additional information. User should also check related baseboard documentation when choosing baseboard design for TE0711-01 module.

A 3.3V supply is also needed and must be supplied from the user's PCB. An output 3.3V supply is available on some of the board connector pins (see section 'Power Rails'). The input 3.3VIN will be switched to the internal 3.3V voltage level after the FPGA 1.0V supply is stable. Than 3.3V supply will be available on the B2B connector pins.

The regulators can be powered from the 3.3V supply or a 5V supply if preferred. The options for powering the board are as follows:

Voltages on B2B- Connectors | B2B JM1-Pin | B2B JM2-Pin | Direction | Note |

|---|---|---|---|---|

| VIN | 1, 3, 5 | 2, 4, 6, 8 | input | supply voltage |

| 3.3VIN | 13, 15 | - | input | supply voltage |

| VCCIO15 | 9, 11 | - | input | high range bank voltage |

| VCCIO34 | - | 1, 3 | input | high range bank voltage |

| VCCIO35 | 7, 9 | input | high range bank voltage | |

| 3.3V | 14 | 10, 12, 91 | output | internal 3.3V voltage level |

| 1.8V | 39 | - | output | internal 1.8V voltage level |

Table 8: Power rails of SoM on B2B connectors

| Bank | Schematic Name | Voltage | Range |

|---|---|---|---|

| 0 Config | 3.3V | 3.3V | - |

| 14 | 3.3V | 3.3V | - |

| 15 | VCCIO15 | user | HR: 1.2V to 3.3V |

| 16 | 1.8V | 1.8V | - |

| 34 | VCCIO34 | user | HR: 1.2V to 3.3V |

| 35 | VCCIO35 | user | HR: 1.2V to 3.3V |

Table 9: Range of FPGA's bank voltages

See the Artix7 datasheet DS181 for the allowable voltage range.

Module Variant | FPGA | FPGA Junction Temperature | Operating Temperature Range |

|---|---|---|---|

| TE0711-01-100-2C | XC7A100T-2CSG324C | 0°C to 85°C | commercial grade |

| TE0711-01-35-2C | XC7A35T-2CSG324C | 0°C to 85°C | commercial grade |

| TE0711-01-100-2I | XC7A100T-2CSG324I | -40°C to 100°C | industrial grade |

| TE0711-01-35-2I | XC7A35T-2CSG324I | -40°C to 100°C | industrial grade |

Table 10: Differences between variants of Module TE0711-01

| Parameter | Min | Max | Units | Notes |

|---|---|---|---|---|

VIN supply voltage | -0.3 | 7.0 | V | EN6347QI / EN5311QI data sheet |

| 3.3VIN supply voltage | -0.1 | 3.6 | V | - |

| PL IO bank supply voltage for HR I/O Banks (VCCO) | -0.5 | 3.6 | V | - |

| I/O input voltage for HR I/O banks | -0.4 | VCCO_X+0.55 | V | - |

| Voltage on module JTAG pins | -0.5 | VCCO_0+0.45 | V | VCCO_0 is 3.3V nominal. |

| Storage temperature | -55 | +125 | °C | - |

Table 11: Absolute maximum ratings

| Parameter | Min | Max | Units | Notes | Reference Document |

|---|---|---|---|---|---|

| VIN supply voltage | 2.4 | 5.5 | V | - | EN5311QI data sheet |

| 3.3VIN supply voltage | 3.135 | 3.465 | V | - | 3,3V ± 5% |

| PL I/O bank supply voltage for HR I/O banks (VCCO) | 1.14 | 3.465 | V | - | Xilinx datasheet DS181 |

| I/O input voltage for HR I/O Banks | - 0.20 | VCCO + 0.2 | V | - | Xilinx datasheet DS181 |

| Voltage on Module JTAG pins | 3.135 | 3.465 | V | - | 3,3V ± 5% |

Table 12: Recommended operation conditions

| Please check Xilinx datasheet (DS181) for complete list of absolute maximum and recommended operating ratings. |

Commercial grade: 0°C to +70°C.

Industrial grade: -40°C to +85°C.

The module operating temperature range depends also on customer design and cooling solution. Please contact us for options.

All dimensions are shown in mm.

Figure 3: Physical Dimensions of the TE0711-01 board

| 20.6 g | Plain module |

| 8.8 g | Set of bolts and nuts |

| Date | Revision | Notes | PCN | Documentation link |

|---|---|---|---|---|

| 01 | First production release Current Hardware Revision |

Hardware revision number is printed on the PCB board together with the module model number separated by the dash.

| Date | Revision | Contributors | Description |

|---|---|---|---|

| 2017-01-01 | TRM revision | ||

| 2015-06-05 | 0.1 |

| initial version |