Electronic Drive Development Platform (EDDP) provides all necessary software and hardware components for development and evaluation of motor control applications. While those components (both software and hardware) can also be used separatly this manual describes EDDP usage with default reference hardware platform (EDDP Kit) only.

Hardware components/boards delivered in EDDP Kit are not intended to be used in finished products. All the software and hardware parts of the EDDP are intended for Developers evaluating Motor Control Applications with Xilinx FPGA and/or SoC Devices. |

It is possible to run the default control firmware and GUI to verify the that the hardware is functional.

Following items are required in addition to EDDP Kit:

In order to pass EMC radiatied emission (EN 55011) class B requirements option "Spread Spectrum" must be activated (standard setting). |

Software version that was used in EMC test: (Visible in the GUI main scren) 2017-7-31 (SVN Tag 5745). |

For development with SDSoC additonal items are required:

For development with HLS additonal items are required:

Micro-SD is delivered without Linux images to avoid any issues related to US export control regulations. |

When delivered as full EDDP Kit several components are pre-assembled.

Motor Adapter Board

The default (Refence) Motor with Encoder is connected to the Driver Board using special "Adapter Board" (TEC0060). In the EDDP Kit the Motor is pre-assembled:

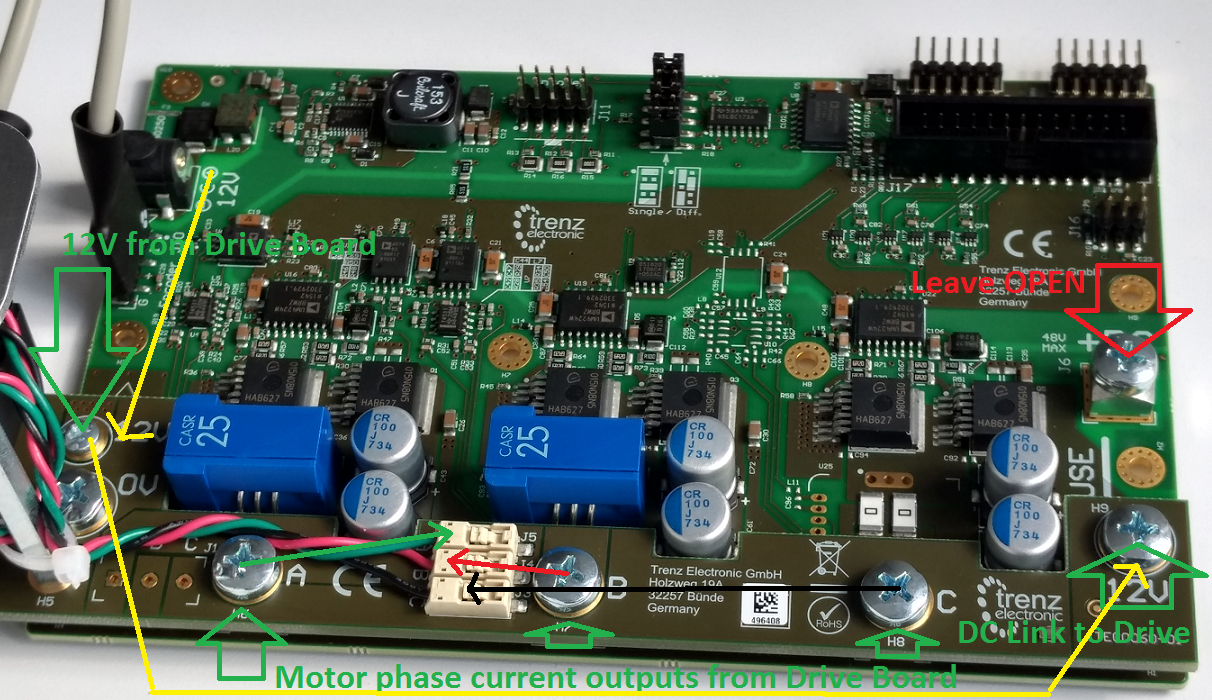

The Adapter board is mounted to Driver Board using 5 x M6 screws (Labels 0V, A, B, C, 12V on Adapter Board) and with M3 screws and spacer - marked 12V at the left. This Adapter board "forwards" the Drive board pre-driver supply (12V) to the DC Link main terminal on the Drive board, so that separate DC Link powersupply is not needed allowing easy evaluation of the complete system.

Note terminal marked+DC must be left open when using the Adapter board!

M3 Spacer and screws connect 12V from from Drive board to Adapter Board.

Motor Connection

When delivered as full EDDP Kit the reference Motor wires are already connected to Adapter board. Instructions for manual assembly below:

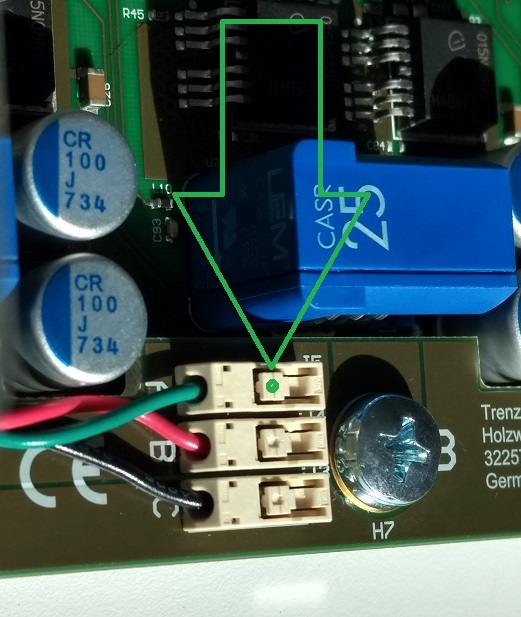

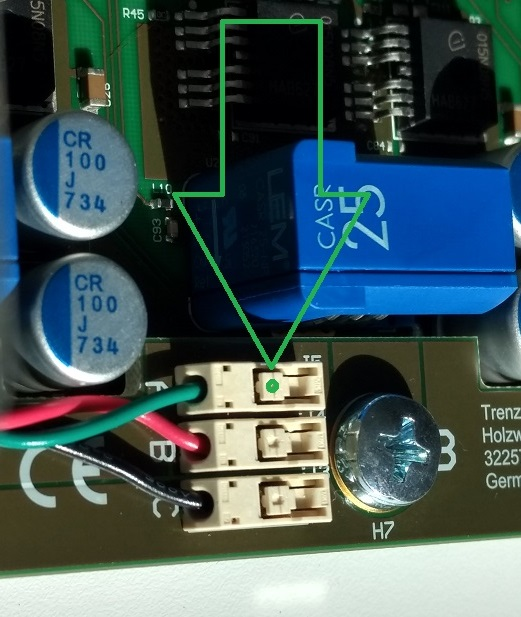

Green dot and arrow mark the place where wire terminal can be released for insertion or removal. Use a ball-point pen or similar tool to apply gentle force at the dot. Please do not try to remove the wires by pulling them out! Do not apply force in other regions of the white plastic than the one marked it is easy to damage the plastic.

Encoder Connection

One 6 Pin PMoD cable is included with the EDDP Kit, it is already assembled between encoder and Drive Board. Instructions for manual assembly below:

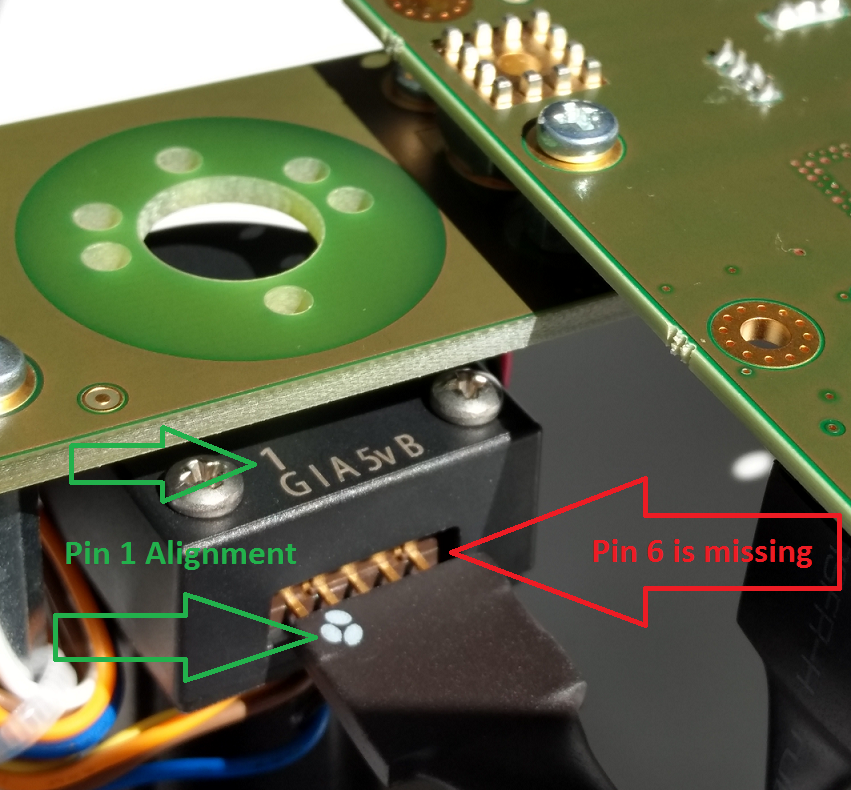

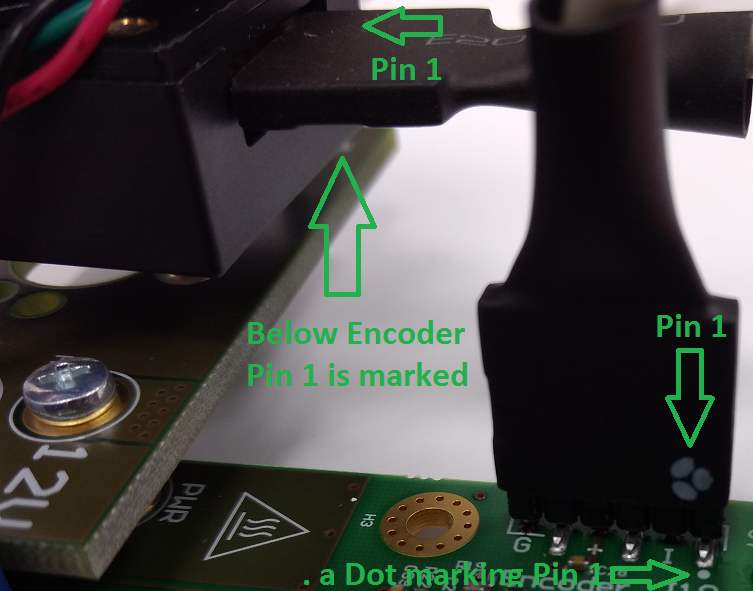

PMoD cable alignment to Encoder connector, notice that there are 5 pins in Encoder header while PMoD female connector has 6 terminals. Red Arrow marks the "empty" terminal at PMoD Cable.

PMoD Cable installation, Pin 1 Markings highlighted, on Drive Board a white dot marks 6 Pin header Pin 1, also marked with "G" (ground). This pin should be aligned to Encoder Pin marked "G" and "1" visible when looking from the bottom up. Please note that Encoder header has 5 terminals while the driver board and PMoD cable have 6 terminals.

EDDP Kit Content

The Motor is pre-mounted to the Driver board using the Adapter Board and accessories. |

The default Control Board is the Digilent ARTY-Z 7010, which is delivered as part of the EDDP Kit. This manual contains information relevent to the actual use of the ARTY-Z as a Control Board within the EDDP only; all technical data and user guides and manuals for the Controller Board are provided by the controller board manufacturer (Digilent Inc.). Use of the other Control boards with the EDPS Driver board is also outside the scope of this manual. Primary support for other control boards is currently provided by QDESYS.

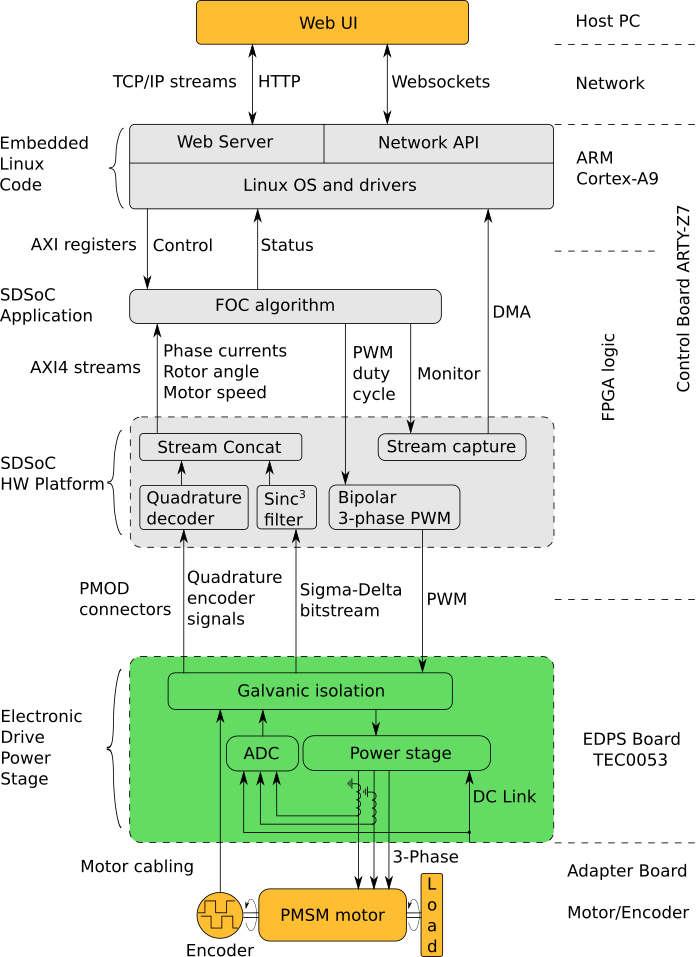

The software delivered on the SD card configures the FPGA on the ARTY-Z board with the Field-Oriented Control algorithm and starts the web server to serve the Web User Interface (Web UI).

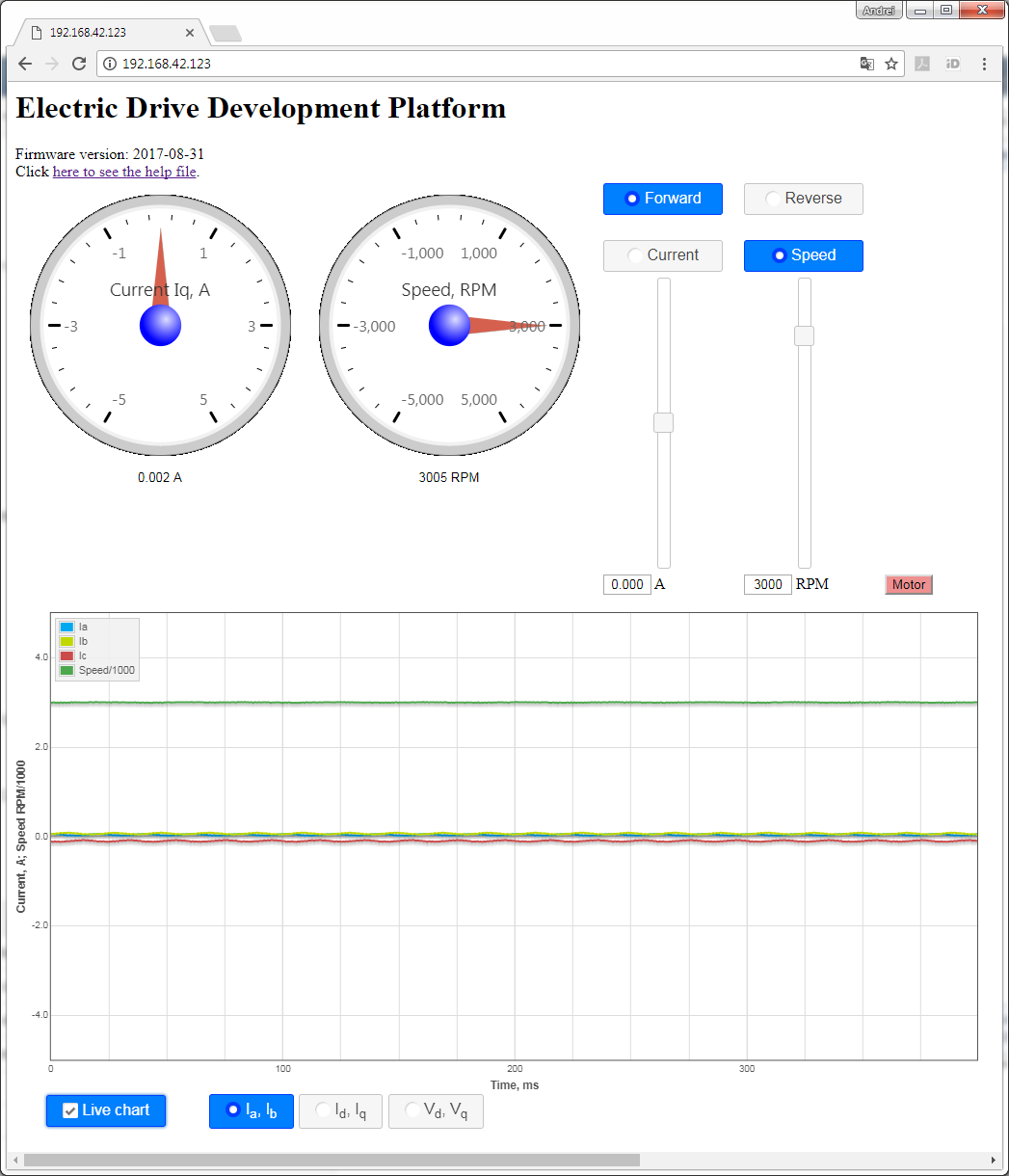

To access the Web UI, point a web browser to the IP of the Controller Board. The following page appears:

To start the motor, click the button "Motor". The motor will make 3 rotations in order to make sure that encoder finds the initial position before starting in correct mode and the button will turn red. To stop the motor, clicke the button "Motor" again; the button will turn green.

The gauges show the stator current Iq and the motor speed in RPM.

To see the charts live, enable checkbox "Live charts". The following charts are available:

The radio buttons "Current" and "Speed" permit switching the control modes.

The sliders permit selecting the target speed and target current when in the appropriate mode. The direction radio buttons "Forward" and "Reverse" will be changed accordingly when the sign of the value is changed.

The radio buttons "Forward" and "Reverse" can be used to change the direction; the target slider will be changed accordingly.

The default motor is supplied in the EDDP Kit; see the chapter Reference Motor for details. Use of custom motors is outside the scope of this manual.

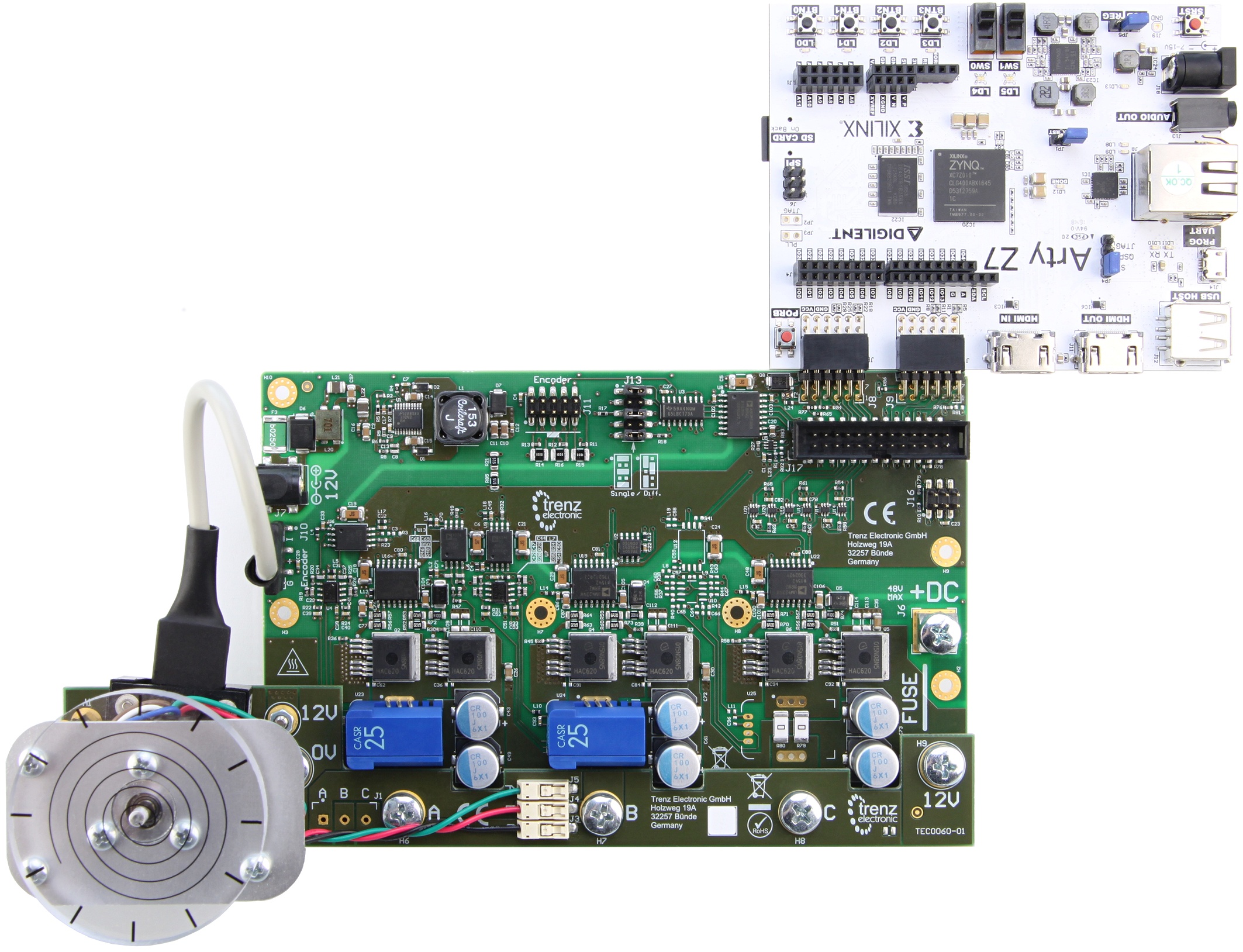

A 3-phase motor with an encoder is connected to the EDPS Driver board (TEC0053). The driver board consists of a 3-phase power stage to be driven by PWM signals, current transducers and Analog Digital Converters (ADC) to measure phase currents and DC Link Voltage and isolating circuitry to provide electrical isolation for the signals to the Control Board.

A TEC0060 board, included in the EDDP Kit, is used as a mechanical and electrical adaptor for the reference motor.

The Control Board provides PWM signals for the Driver Board and interface to the ADC's.

List of the documents for further information:

| Title | Description |

|---|---|

| FOC SDSoC | Implementation of a Field-Oriented Control algorithm in C++ with Vivado SDSoC |

| SDSoC Hardware Platform ARTY-Z7 | A basis for building Vivado SDSoC applications running on an Arty-Z7 board connected to a TEC0053 board |

| AXI4-Stream AD7403 | An IP core for filtering the delta-sigma bitstream read from one or more ADC-s of type of AD7403 to an AXI4-Stream of samples |

| AXI4-Stream Encoder | An IP core for converting impulses from a relative index encoder with an index signal to an AXI4-Stream of position and speed data |

| AXI4-Stream PWM | An IP core for generating PWM signals according to the input AXI4-Stream |

| AXI4-Stream Concat | An IP core for concatenating AXI4-Streams |

| Web GUI | A Web UI to control and monitor an EDPS board over the Network API |

| Network API | A communication protocol, based on Websockets, to control an EDPS board |

| Embedded Linux Code | A server program interfacing to an EDPS board and implementing the Network API and the functions of a Web Server |