Table of Contents

<!-- Template Revision 1.66 (HTML comments will be not displayed in the document, no need to remove them. For Template/Skeleton changes, increase Template Revision number. So we can check faster, if the TRM style is up to date). --> |

<!-- General Notes: If some section is CPLD firmware dependent, make a note and if available link to the CPLD firmware description. It's in the TE shop download area in the corresponding module -> revision -> firmware folder. --> |

<!-- General Notes: Designate all graphics and pictures with a number and a description. For example "Figure 1: TE07xx-xx Block Diagram" or "Table 1: Initial delivery state". "Figure x" and "Table x" have to be formatted to bold. --> |

Table of Contents |

<!-- Wiki Link: Go to Base Folder of the Module or Carrier, for example : https://wiki.trenz-electronic.de/display/PD/TE0712 --> |

Refer to http://trenz.org/tem0002-info for the current online version of this manual and other available documentation. |

The Trenz Electronic TEM0002-01 SmartBerry with Raspberry Pi form factor, is an industrial-grade module based on Microsemi SmartFusion2 SoC (System on a Chip). The Module has 128MB DDR3 SDRAM, a Gigabit Ethernet PHY, four Pmods, a GPIO Pin header compatible to the Raspberry Pi pinout and a Micro USB to UART interface. SmartFusion2 combines a 166 MHz Cortex-M3 core with 256 KByte Flash, 80 KByte SRAM and a 12 kLUT FPGA core logic.

1 x RGB LED

Additional assembly options are available for cost or performance optimization upon request.

|

|

Storage device name | Content | Notes |

|---|---|---|

| Microsemi SmartFusion2 SoC FPGA, U2 | Demo Design | - |

| EEPROM, U6 | Programmed | FTDI (FT2232H) configuration data. |

Table 1: Initial delivery state of programmable devices on the module.

The SmartBerry supports configuration of the system via JTAG by the FTDI USB bridge.

<!-- Connections and Interfaces or B2B Pin's which are accessible by User --> |

26 I/O signals provided on the Rasperry Pi compatible header are connected to banks with 3.3V. Dpending on the configuration of the SoC, also GPIOs of the Microprocessor subsystem can be routet to the SoC Pins.

| FPGA SoC Signal | SOC Pin | Header Pin | Raspberry Pi Signal |

|---|---|---|---|

| MSIO19PB2 | U2-H16 | 3 | GPIO2 |

| MSIO16PB2 | U2-J17 | 5 | GPIO3 |

| MSIO2PB2 | U2-T18 | 7 | GPIO4 |

| MSIO1PB2 | U2-U18 | 8 | GPIO14 |

| MSIO5NB2 | U2-R18 | 10 | GPIO15 |

| MSIO11NB2 | U2-M17 | 11 | GPIO17 |

| MSIO6PB2 | U2-P18 | 12 | GPIO18 |

| MSIO14PB2 | U2-L15 | 13 | GPIO27 |

| MSIO17PB2 | U2-K16 | 15 | GPIO22 |

| MSIO11PB2 | U2-N16 | 16 | GPIO23 |

| MSIO27NB1 | U2-B19 | 18 | GPIO24 |

| MSIO25NB1 | U2-C20 | 19 | GPIO10 |

| MSIO25PB1 | U2-D20 | 21 | GPIO9 |

| MSIO22NB1 | U2-F18 | 22 | GPIO25 |

| MSIO20NB2 | U2-F20 | 23 | GPIO11 |

| MSIO20PB2 | U2-G19 | 24 | GPIO08 |

| MSIO18PB2 | U2-H19 | 26 | GPIO07 |

| MSIO28PB1 | U2-A20 | 27 | ID_SDA |

| MSIO28NB1 | U2-A19 | 28 | ID_SCL |

| MSIO16NB2 | U2-J18 | 29 | GPIO05 |

| MSIO15NB2 | U2-J20 | 31 | GPIO06 |

| MSIO15PB2 | U2-K20 | 32 | GPIO12 |

| MSIO14NB2 | U2-L16 | 33 | GPIO13 |

| MSIO13NB2 | U2-L19 | 35 | GPIO19 |

| MSIO13PB2 | U2-L20 | 36 | GPIO16 |

| MSIO8PB2 | U2-N20 | 37 | GPIO26 |

| MSIO8NB2 | U2-M19 | 38 | GPIO20 |

| MSIO4NB2 | U2-N19 | 40 | GPIO21 |

Table 2: General overview of I/O signals connected to the SoC.

Further I/Os are provided via the Pmod connectors descriebed below.

The module provides four 2x6 female Pmod connectors. Two of the headers (P2 and P3) are arranged to use as dual 12 pin Pmod. According to the standard on all four headers Pin 5 and 11 are connected to ground, 6 and 12 to 3.3V.

| FPGA SoC Signal | Pin | Pmod Signal | Pmod Pin |

|---|---|---|---|

| MSIO71PB7 | U2-F3 | PB-01 | P1-1 |

| MSIO71NB7 | U2-F4 | PB-02 | P1-2 |

| MSIO68NB7 | U2-E3 | PB-03 | P1-3 |

| MSIO80NB7 | U2-H4 | PB-04 | P1-4 |

| MSIO75PB7 | U2-G4 | PB-05 | P1-7 |

| MSIO75NB7 | U2-F5 | PB-06 | P1-8 |

| MSIO67NB7 | U2-E5 | PB-07 | P1-9 |

| MSIO78NB7 | U2-G3 | PB-08 | P1-10 |

| MSIO79PB7 | U2-G1 | PC-01 | P2-1 |

| MSIO79NB7 | U2-F1 | PC-02 | P2-2 |

| MSIO70NB7 | U2-E2 | PC-03 | P2-3 |

| MSIO64PB7 | U2-C1 | PC-04 | P2-4 |

| MSIO78PB7 | U2-G2 | PC-05 | P2-7 |

| MSIO70PB7 | U2-E1 | PC-06 | P2-8 |

| MSIO68PB7 | U2-D2 | PC-07 | P2-9 |

| MSIO64NB7 | U2-C2 | PC-08 | P2-10 |

| MSIO117NB4 | U2-Y16 | PA-01 | P3-1 |

| MSIO117PB4 | U2-Y15 | PA-02 | P3-2 |

| MSIO112PB4 | U2-W13 | PA-03 | P3-3 |

| MSIO110PB4 | U2-V12 | PA-04 | P3-4 |

| MSIO118PB4 | U2-W15 | PA-05 | P3-7 |

| MSIO112NB4 | U2-W14 | PA-06 | P3-8 |

| MSIO105NB4 | U2-Y13 | PA-07 | P3-9 |

| MSIO104PB4 | U2-V11 | PA-08 | P3-10 |

| MSIO4PB2 | U2-P20 | PD-01 | P4-1 |

| MSIO3NB2 | U2-R20 | PD-02 | P4-2 |

| MSIO2NB2 | U2-T19 | PD-03 | P4-3 |

| MSIO0PB2 | U2-V20 | PD-04 | P4-4 |

| MSIO6NB2 | U2-P19 | PD-05 | P4-7 |

| MSIO3PB2 | U2-T20 | PD-06 | P4-8 |

| MSIO1NB2 | U2-U19 | PD-07 | P4-9 |

| MSIO0NB2 | U2-V19 | PD-08 | P4-10 |

Table 3: Overview of Pmod signals connected to the SoC.

JTAG access to the SoC components is provided through the micro usb connector via the FTDI usb to UART bridge. Depending on the jumper J6 the JTAGSEL signal SW3 switches the JTAG interface to either the FPGA fabric TAP (OPEN, high) or the Cortex-M3 JTAG debug interface (CLOSED, low). JTAG signals are powered by 3.3V.

FTDI signal | pin | JTAG Signal | Microsemi SmartFusion2 SoC pin |

|---|---|---|---|

| ADBUS0 | U3-12 | TCK | U2-W19 |

| ADBUS1 | U3-13 | TDI | U2-V16 |

| ADBUS2 | U3-14 | TDO | U2-Y20 |

| ADBUS3 | U3-15 | TMS | U2-V17 |

Table 4: JTAG interface signals.

The SD Card interface is connected to bank 2 of the SoC

| FPGA / SoC Pin | Connected To | Signal Name | Notes |

|---|---|---|---|

| U2-H16 | J3-9 | SD_CD | Card detect switch |

| U2-N15 | J3-7 | SD_D0 | |

| U2-G18 | J3-8 | SD_D1 | |

| U2-R16 | J3-1 | SD_D2 | |

| U2-R17 | J3-2 | SD_D3 | |

| U2-R15 | J3-3 | SD_CMD | |

| U2-P15 | J3-5 | SD_CLK |

Table 5: SD Card interface signals and connections.

| PHY Pin | Signal | Microsemi SmartFusion2 SoC signal | Pin | Notes |

|---|---|---|---|---|

| U1-25 | ETH_TXCK | MSIOD84PB6 | U2-K7 | |

| U1-23 | ETH_TXCTL | MSIOD87NB6 | U2-K3 | |

| U1-26 | ETH_TXD0 | MSIOD93PB6 | U2-L1 | |

| U1-28 | ETH_TXD1 | MSIOD97NB6 | U2-M2 | |

| U1-29 | ETH_TXD2 | MSIOD97PB6 | U2-M1 | |

| U1-30 | ETH_TXD3 | MSIOD95PB6 | U2-M3 | |

| U1-22 | ETH_RRXCK | MSIOD84PB6 | U2-J2 | |

| U1-21 | ETH_RRXCTL | MSIOD93NB6 | U2-K1 | |

| U1-20 | ETH_RRXD0 | MSIOD86PB6 | U2-K5 | |

U1-18 | ETH_RRXD1 | MSIOD82PB6 | U2-H1 | |

| U1-17 | ETH_RRXD2 | MSIOD82NB6 | U2-H2 | |

| U1-16 | ETH_RRXD3 | MSIOD83PB6 | U2-J4 | |

| U1-31 | ETH_MDC | MSIOD99PB6 | U2-N1 | |

| U1-33 | ETH_MDIO | MSIOD99NB6 | U2-N2 | |

| U1-34 | ETH_MDINT | MSIOD98PB6 | U2-N4 | |

| U1-35 | ETH_RST | MSIO114PB4 | U2-R13 | |

| U1-36 | PHY_RCLKOUT | MSIO102NB4/CCC_NE1_CLKIO | U2-W10 | |

| U1-39 | PHY_LED0 | MSIO104NB4 | U2-U11 | |

| U1-38 | PHY_LED1 | MSIO116PB4 | U2_T14 |

Table 6: Ethernet PHY signals and connections.

There are no on-board I2C devices. For Raspberry Pi compability the device detection I2C bus is routed from the header J8-27/28 to Bank 1 U2-A20/A19 (SDA/SCL).

| I2C Device | I2C Address | Notes |

|---|---|---|

| Header J8 | 0x50 | Device detection/identification. |

Table 7: I2C slave device addresses.

<!-- Components on the Module, like Flash, PLL, PHY... --> |

TEM0002 has 1Gb industrial grade DDR3 SDRAM (U5). A 16-bit wide memory bus providing total of 128 MBytes of on-board RAM. Specification is 800 MHz clocking resulting in 1600 Mb/s data rate and timings of 11-11-11 (CL-TRCD-TRP).

On-board Gigabit Ethernet PHY (J2) is provided by Microsemi VSC8531 chip (U1). The Ethernet PHY RGMII interface is connected to bank 6 of the Microsemi SOC. I/O voltage is fixed at 1.5V. The reference clock input of the PHY is supplied from an external 25.000000 MHz oscillator (U11).

The module has following reference clock signals provided by on-board oscillators:

| Clock Source | Schematic Name | Frequency | Clock Destination |

|---|---|---|---|

| Crystal CX3225CA25000D0HSSCC | Y1 | 25.000 MHz1 | SmartFusion2 SoC U2 Main XTAL |

| Crystal ECX-31B | Y2 | 32.768 KHz | SmartFusion2 SoC U2 AUX XTAL |

| SiTime SiT8008AI oscillator | U11 | 25.000000 MHz | Gb Ethernet Copper PHY U1A |

| SiTime SiT8008AI oscillator | U14 | 25.000000 MHz | SmartFusion2 SoC U2-Y12 Bank 4 |

Table 8: Reference clock signals.

1In REV02, Y1 will be replaced by a 12 MHz crystal.

| LED | Color | Connected to | SoC FPGA Signal | Description and Notes |

|---|---|---|---|---|

| D1 | Red | U2-G16 Bank 1 | MSIO21PB1 | |

| D2 | Green | U2-G17 Bank 1 | MSIO21NB1 | |

| D3 | RGB | U2-H5 Bank 7, U2-F6 Bank 7, U2-H6 Bank 7 | MSIO80PB7, MSIO67PB7, MSIO81NB7 | |

| J2 | Green, Yellow | U2-Y10 Bank 4, U2-U12 Bank 4 | MSIO102PB4, MSIO110NB4 | Ethernet: LED1A, LED1B |

| J2 | Green, Yellow | U2-V14 Bank 4, U2-U14 Bank 4 | MSIO115PB4, MSIO115PB4 | Ethernet: LED2A, LED2B |

Table 9: On-board LEDs.

| Button | Connected to | SoC FPGA Signal |

|---|---|---|

| S4 | U2-E17 Bank 1 | MSIO24PB1 |

| S5 | U2-E16 Bank 1 | MSIO24NB1 |

Table 10: On-board Buttons.

There is no specific power on Sequence. Just supply with 5V via the micro USB J1 or the J5 PWR_IN with current rating sufficient for your Design.

<!-- If power sequencing and distribution is not so much, you can join both sub sections together --> |

The maximum power consumption of a module mainly depends on the design running on the FPGA.

| Power Input | Typical Current |

|---|---|

| VIN | TBD* |

| 3.3VIN | TBD* |

Table 11: Typical power consumption.

* TBD - To Be Determined soon with reference design setup.

Power supply with minimum current capability of ...A for system startup is recommended.

For the lowest power consumption and highest efficiency of the on-board DC-DC regulators it is recommended to power the module from one single 3.3V supply. All input power supplies have a nominal value of 3.3V. Although the input power supplies can be powered up in any order, it is recommended to power them up simultaneously.

|

Power Rail Name | Connector pin | Direction | Notes |

|---|---|---|---|

| VIN | J5-1 | Input | Main supply voltage. |

| 5V | J8-2, J8-4 | Output | |

| 3.3V | J8-1, J8-17 | Output | |

| 1.5V | - | Output | |

1.2V | - | Output | |

| GND | J5-2, J8-9/25/39/6/14/20/30/34 |

Table 12: Module power rails.

Bank | Schematic Name | Voltage | Voltage Range |

|---|---|---|---|

| 0 (DDR3) | 1.5V | 1.5V | - |

| 1 | 3.3V | 3.3V | - |

| 2 | 3.3V | 3.3V | - |

| 3 | 3.3V | 3.3V | - |

| 4 | 3.3V | 3.3V | - |

| 5 | 1.5V | 1.5V | - |

| 6 | 1.5V | 1.5V | - |

| 7 | 3.3V | 3.3V | - |

Table 13: I/O bank voltages.

| Module Variant | FPGA / SoC | Operating Temperature | Temperature Range |

|---|---|---|---|

| TEM0002-01 | M2S010 | 0°C to +70°C | commercial |

Table 14: Module variants.

Parameter | Min | Max | Units | Reference Document |

|---|---|---|---|---|

VIN supply voltage | -0.3 | 6.0 | V | - |

Storage temperature1 | -25 | 70 | °C | - |

Table 15: Module absolute maximum ratings.

1Boundary determined by the specification of the buttons, all other components have at least a range of -40°C to 85°C.

| Parameter | Min | Max | Units | Reference Document |

|---|---|---|---|---|

| VIN supply voltage | 2.4 | 5.5 | V | - |

| Operating temperature1 | 0 | 70 | °C | - |

Table 16: Module recommended operating conditions.

1Upper bound is determined by the buttons, all other components have at least a upper bound of 85 °C.

Module operating temperature range depends also on customer design and cooling solution. Please contact us for options.

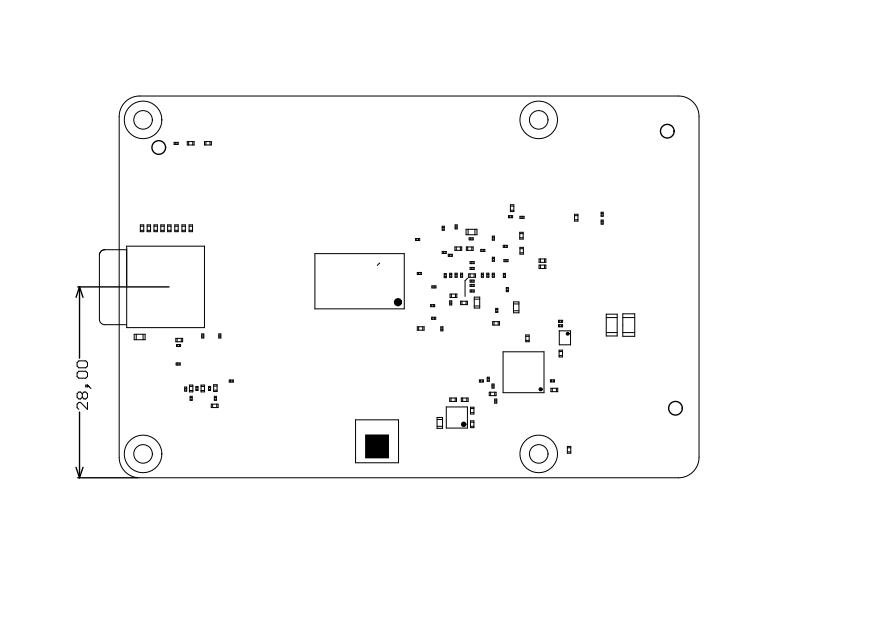

Module size: 85 mm × 56 mm. Please download the assembly diagram for exact numbers.

PCB thickness: 1.55 mm.

Highest part on PCB: top approx. 13.3 mm (Ethernet), bottom 1.57mm (SD-Card)Please download the step model for exact numbers.

All dimensions are given in millimeters.

|

| Date | Revision | Notes | PCN | Documentation Link |

|---|---|---|---|---|

| - | 01 | Prototypes |

Table 17: Module hardware revision history.

Hardware revision number can be found on the PCB board together with the module model number separated by the dash.

![]()

Figure 5: Module hardware revision number.

<!-- Generate new entry: 1.add new row below first 2.Copy "Page Information Macro(date)" Macro-Preview, Metadata Version number, Author Name and description to the empty row. Important Revision number must be the same as the Wiki document revision number 3.Update Metadata = "Page Information Macro (current-version)" Preview+1 and add Author and change description. --> |

Date | Revision | Contributors | Description |

|---|---|---|---|

| |||

all | Jan Kumann, John Hartfiel |

Table 18: Document change history.