Page History

...

This User Manual describes the Electronic Drive Development Platform (EDDP) main concepts.

| Note |

|---|

None of the EDDP components is are intended to be used in finished products, all . All the software and hardware parts of the Platform are intended for Developers evaluating Motor Control Applications with Xilinx FPGA and/or SoC Devices. |

...

Functional description - TODO

Control Board

The default Control Board is the Digilent ARTY-Z 7010 is considerd as primary and default Control Board for EDDP as it , which is delivered as part of the EDDP Kit. In all cases the documentation for the Control Board is not considered part of this manual. All This manual contains information relevent to the actual use of the ARTY-Z as a Control Board within the EDDP only; all technical data and user guides and manuals for the Controller Board are provided by the controller board manufacturer. This manual describes only information relevent to the actual use of ARTY-Z as Control Board within the scope of EDDP.

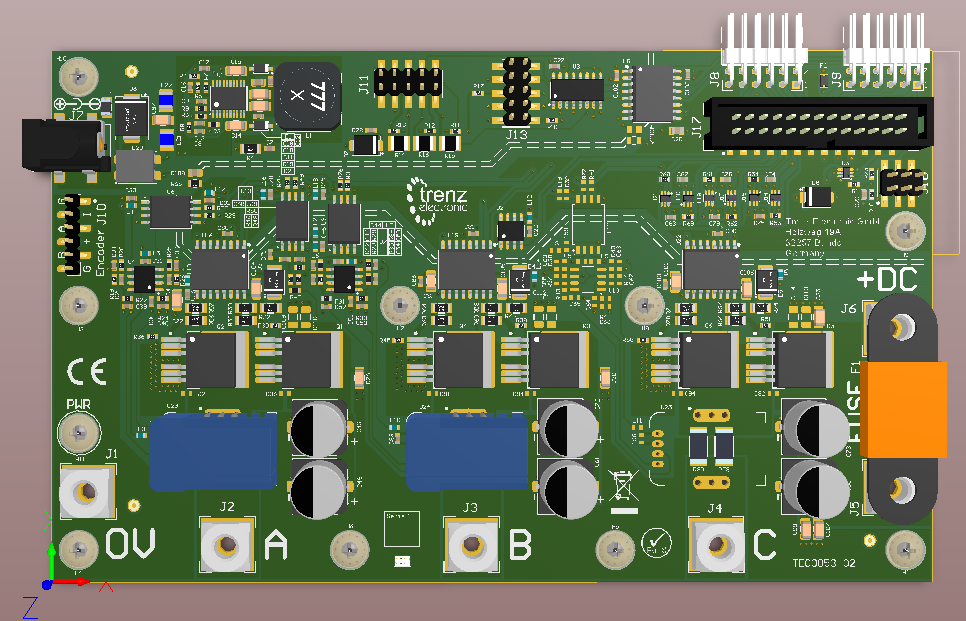

EDPS Board TEC0053

Key Features

- Motor Evaluation evaluation with a an FPGA controller board, recommended with the Digilent Arty Z7 board

- Quick evaluation with reference motor board

- Power option up to 48V and 30A main supply current

...

- MOSFET drivers for 3-phase BLDC Motors

- Current measurement for 2-phases (3 phase measurement optional)

- Temperature sensor on board and 1-Wire bus external option

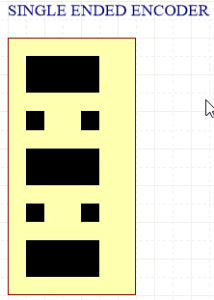

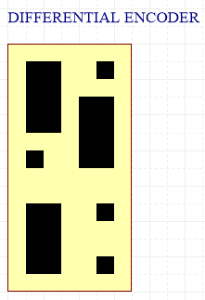

- Encoder input (differential or capable of receiving both single ended and differential signals)

Scope of Delivery

- This The Eval Board comes with the already mounted and wired "Reference Motor Board"

- One "Arty Z7" Board: http://store.digilentinc.com/arty-z7-apsoc-zynq-7000-development-board-for-makers-and-hobbyists/usable with the reference FPGA IPs: TODO insert link

- Any DC +12V must be supplied to both boards supply connectors

(Two AC/DC Wall Mount Adapters are delivered as optional DC +12V power source) - One FUSE F1 30A for motor supply option 2

...

- This product is only allowed to be used by an electrical specialist.

- This product is not allowed to be used unattended.

- There is a possible risk of burns due to hot surfaces while running the Board. This e.g. might be caused by an overcurrent at the motor outputs.

- All externally connected power sources must be SELV protected (Separated or safety extra-low voltage).

- For set up the wiring switch off or disconnect all external power supplies.

- During operations it is not allowed to change the wiring or mechanical setup.

- This product is only allowed to be used in a dry an indoor environment.

- The product is only allowed to be used in horizontal position on a non-conducting and non-inflammable surface.

- The mechanical setup must ensure that the whole test setup can not be dropped to the floor or moved accidentlyaccidentally.

Signals, Interfaces and Pins

Control Board Connections

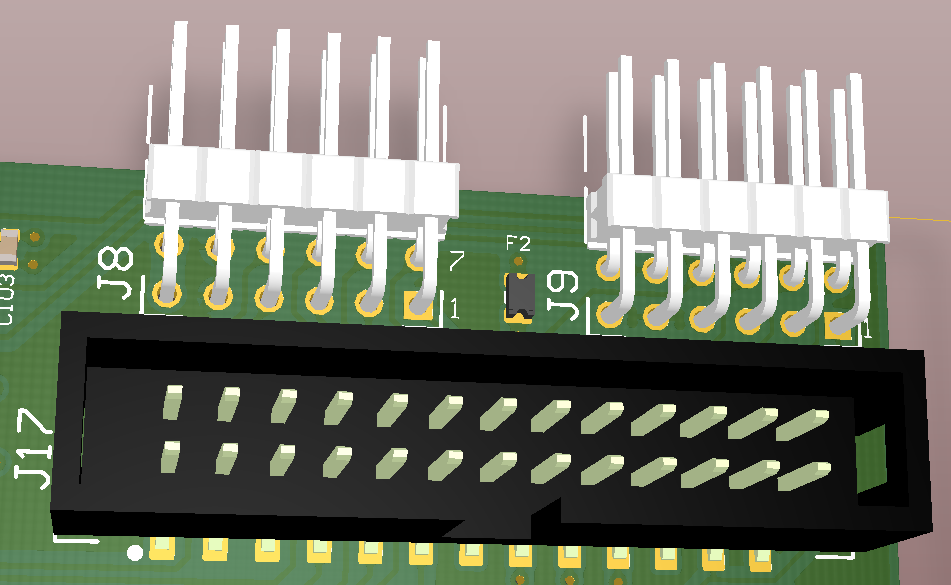

| SignalnamesSignal names | Connector J8 | Connector J9 | Connector J17 |

|---|---|---|---|

Digital Supply to EDPS | Pin 6, 12: +3.3V | Pin 6, 12: +3.3V Pin 5, 11: GND | Pin 5, 6, 21, 22: +3.3V Pin 1, 2, 25, 26: GND |

Motor Driver PWM Signals to EDPS High and Low Side control signals

| Pin 1: G1H - Ch.A HighSide | Pin 11: G1H - Ch.A HighSide | |

| ADC Clock Signal to EDPS | Pin 1: SCLK | Pin 23: SCLK | |

| Encoder Digital Signals from EDPS | Pin 8: ENC_A | Pin 20: ENC_A | |

| Motor Current ADC "raw" Signals from EDPS (usable with FPGA IP) | Pin 2: SDI1 - Current Ch.A | Pin 19: SDI1 - Current Ch.A | |

| Supply Voltage ADC "raw" Signal from EDPS (usable with FPGA IP) | Pin 7: SDIV - from DC_LINK | Pin 24: SDIV - from DC_LINK | |

| 1-Wire bus for temperature measurement | Pin 10: EXT1 - 1-Wire Bus 1 Pin 4: EXT2 - 1-Wire Bus 2 | Pin 4: EXT1 - 1-Wire Bus 1 | |

| Not connected pins | none | none | Pin 13, 14 |

Motor and Power

...

Connections

There are two options available for the motor and power concept:

| Detail | Option 1: Reference Motor Board with DC +12V Supply | Option 2: Customer Motor at individual DC +5..48V | CommentComments |

|---|---|---|---|

| Motor Supply | From DC +12V Input J7 via Fuse F3 (TODO ... A) | From customer DC Supply to J6 via F1 on Eval Boad | |

| Motor Connection | Motor wires connected to cage clamps on Motor Reference Board J5 (A), J4 (B), J3 (C) | Motor wires connected to bolt screw terminals on Eval Board J2 (A), J3 (B), J4 (C) | |

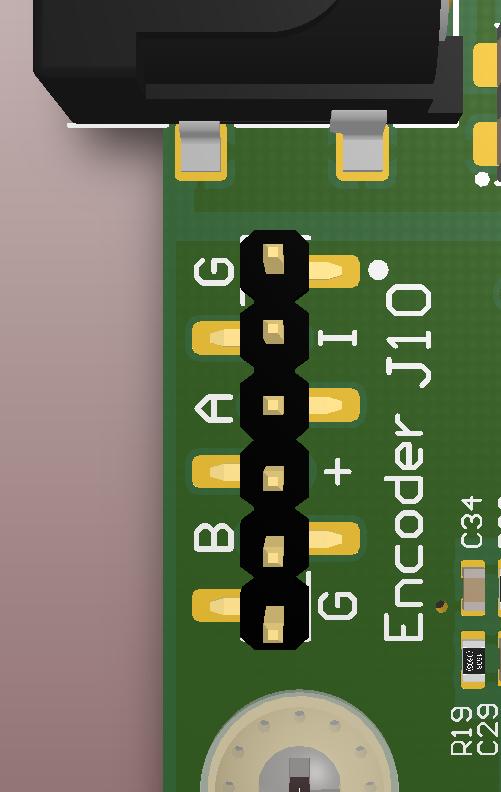

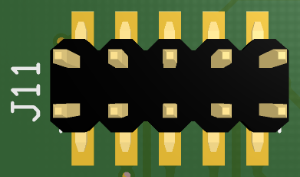

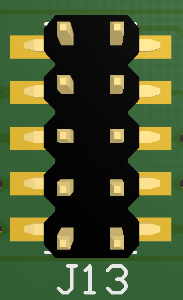

| Encoder Connection | From encoder pins via ribbon cable to Eval Board J10, J11 single ended: | From motor to Eval Board J10 (only single ende signals) see left colomn, or to J11 (single OR differential signals): J11 single ended: J11 differential with 100R terminated: | Jumper Settings for encoder signals.

|

...

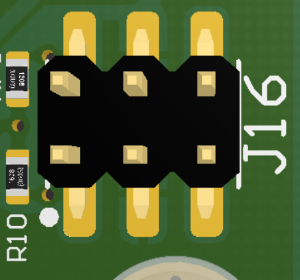

Onboard is a Maxim 1-Wire Temperature sensor DS18S20Z+. This sensor is located at in the middle of the PCB.

Addional 1-Wire temperature sensor(s) can be connected by wires to the connector J16:

- Pin 1(DQ), 3 (GND),5 (+3.3V) at the same 1-wire bus as the onboard one

- Pin 2(DQ), 4 (GND),6 (+3.3V) at a separate 1-wire bus

...

DC 12V Supply Motor and Driver

This externally The power supply sources source must be SELV protected (Separated or safety extra-low voltage) protected.

The motor drivers and the reference motor on the pre-mounted motor board TEC0060 are supplied by this voltage.

The internal +5V digital supply is generated out of from this +12V supply.

DC 5...48V Supply for Motor only

...

Externally power supply for the motor must be SELV protected (Separated or safety extra-low voltage) protected.

This option is

- only allowed to be used for electrical specialist for the used electrical voltage and power conditions

- only allowed to be used under electrical laboratory conditions

- only allowed to be used in horizontal position on a non-conducting and non-inflammable surface

- only allowed to be used with a wiring, which fulfills the current rating for the maximum possible currents.

- only allowed to be used with a suitable current limiting circuit

- The maximum continuous current must not exceed 30A.

- The delivered fuse "Littelfuse Tpye 142.5631.5302" must be used as current limiter between connector J5 and J6.

- To limit the current for smaller motor loads an ADDITIONALLY appropriate current limiter can be used e.g. a current limited power source or a fuse integrated in the wiring.

- only allowed to be used with appropriate connectors at the M5 screw connectors, which means M5 cable lugs must be used and fastened according to technical standards.

- only allowed to be used, if the "Eval Boad high current signals" conducting up to 30A nominal, are covered by isolating, mechanically stable, non-inflammable (UL V-1 or better) material

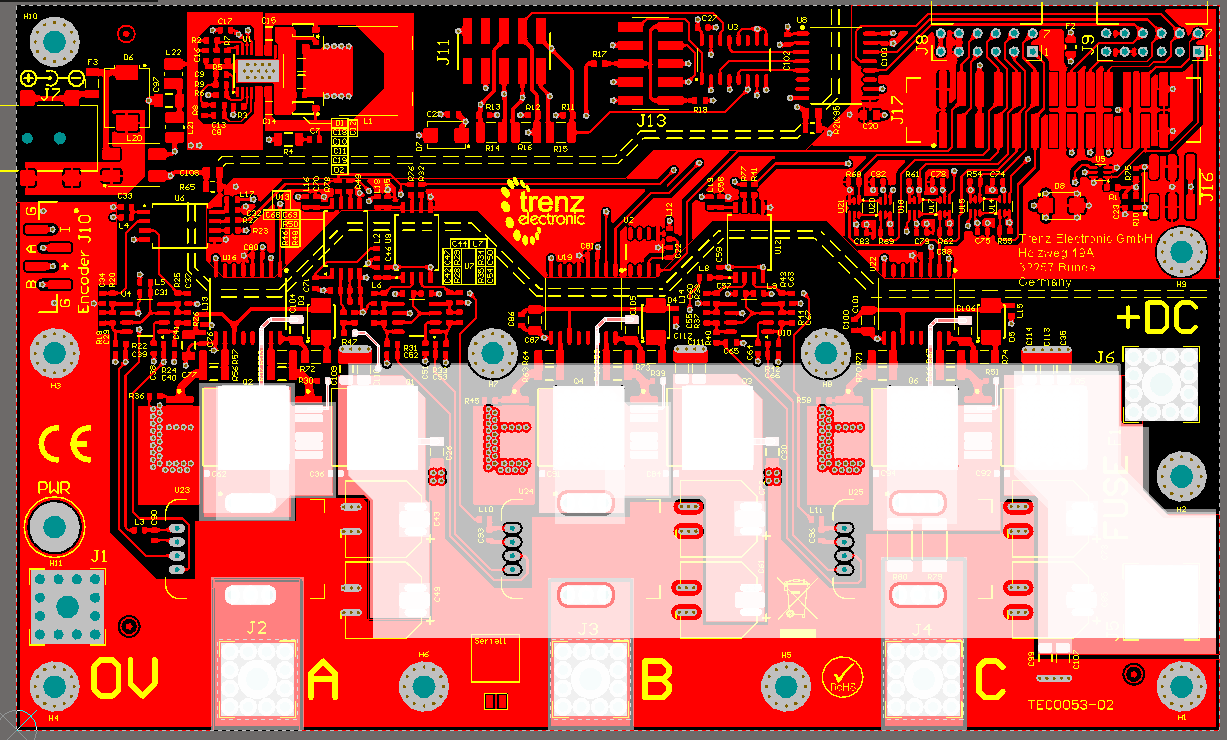

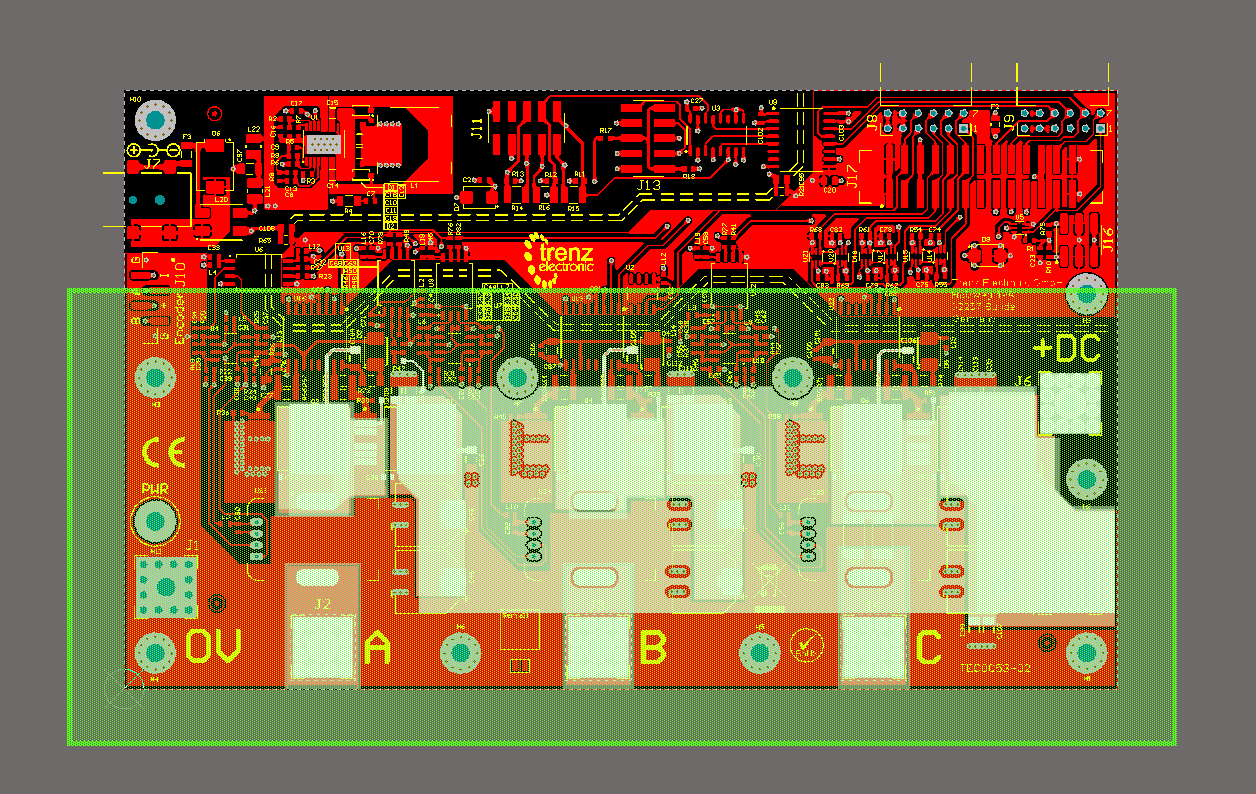

The "Eval Boad high current signals" are the motor outputs A, B, C and Fuse F1 Connectors J5 an J6 and further internal connections shown white marked in the following picture:

- As minimum protection it is mandatory to use the delivered "Isolating cover PCB" (marked in green), which must be mounted to the mounting holes H1, H9, H3, H4 with the delivered 10mm isolating spacers:

- The used cable lugs need to be isolated in the area outstanding the outer border of the Eval Board.

Intention is to make Make sure that the "Isolating Cover PCB" is overlapping the conducting material by a minimum of 2 cm20 mm.

Initial operation

The option 2 motor supply is only usable after To use a separate power supply for the motor supply perform the following steps are done:

- Disconnecting Disconnect the reference motor board TEC0060 by unmounting its screws and the encoder cable from J10

- Mounting Mount the delivered 30A Fuse fuse to the connectors J5 and J6 with the delivered M5 screws

- For lower supply current requirements, caused by the power rating of the used motor, a fuse with a lower and suitable current rating integrated in the supply wiring is recommended.

- Connecting Connect with a cable lugs the +DC 5..48V to J6 and the corresponding GND to J1.

- The cable length is limited to 3m.

- Connection Connect the three motor phases to J2 (A), J3 (B) and J4 (C).

- The cable length is limited to 3m.

- Optional: connect the encoder wires to J10 or J11

and set jumper field according to signal specification: differential or single ended

. See section TODO for details.

Power Consumption

Test Condition:

| VIN Current mA | Notes |

|---|---|---|

| TEC0053-03 +3V3 | TODO mA | |

| TEC0053-03 +12V | TODO mA |

...

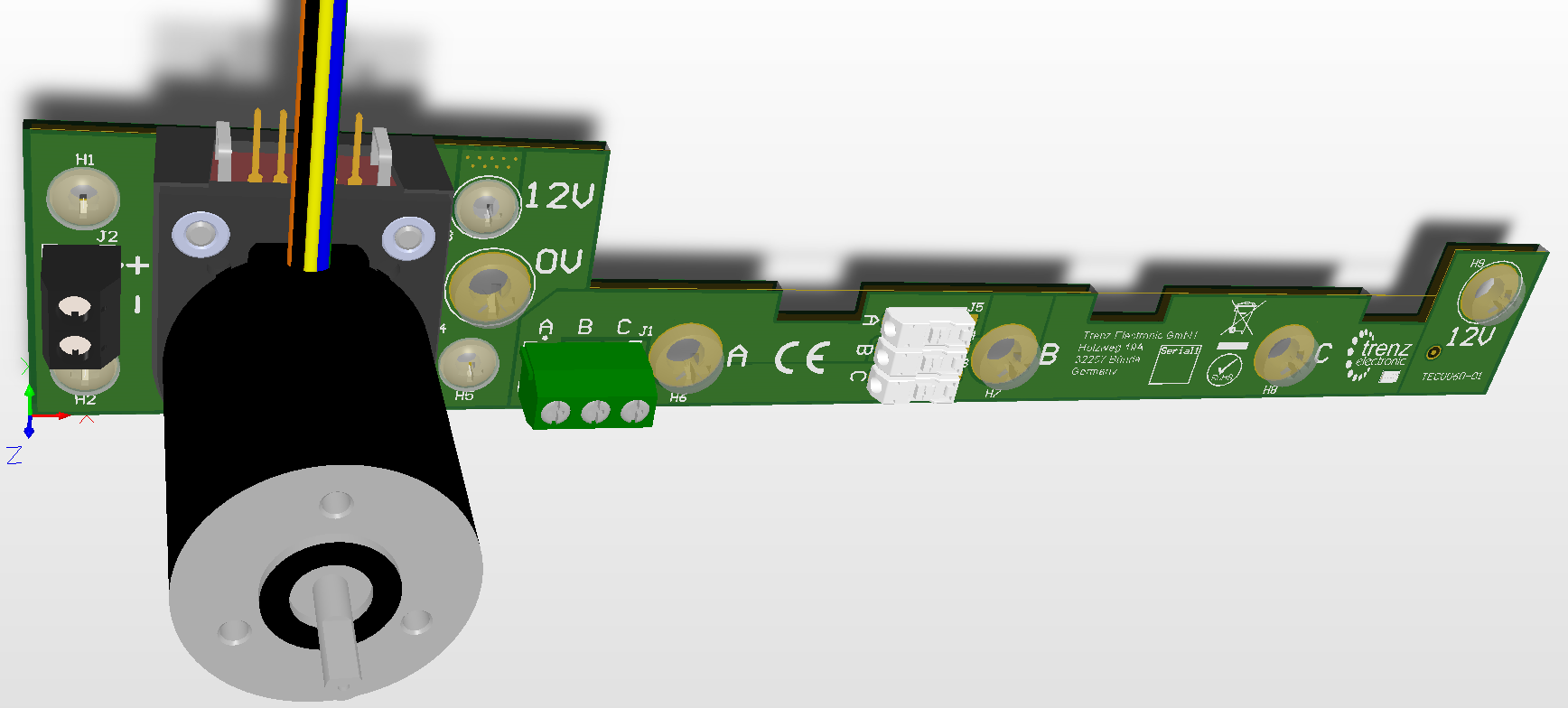

For easy connection of the reference Motor and Encoder to the Driver board a special Motor Adapter Board TEC0060 is included in the EDDP Kit.

Reference Motor

The manufaturer of the reference motor is manufactured by Anaheim Automation and the . The order code of the delivered combination of for the motor with the encoder already mounted is BLWR111D-24V-10000-1000SI. Please note that the encoder is not available separatly, they are premounted to the motor at the manufacturer.

separately. The nominal motor voltage is DC 24V which , however, only 12V is supplied by DC 12V on the Reference Motor Board. This will cause a certain derating in performace, which results in reduced performance.

The datasheet for the motor can be found at:

http://www.anaheimautomation.com/manuals/brushless/L010234%20-%20BLWR11%20Series%20Product%20Sheet.pdf

The datasheet for the encoder :can be found at

http://www.anaheimautomation.com/manuals/accessories/L010390%20-%20Single%20Ended%20Encoder%20with%20Index%20Channel.pdf

...