Overview

The Trenz Electronic TEP0001 is an industrial-grade dual CAN FD transceiver with Pmod interface.

Features

- Digilent Pmod interface compatible

- Dual CAN FD PHY's (CAN0 and CAN1)

- Texas Instruments TCAN337G

- Up to 5Mbit data rate

- Compatible with ISO 11898-2

- Bus pin fault protection of ±14 V

Integrated 12 kV IEC-61000-4-2 ESD contact discharge protection

- 10 pin headers (IDC cable to DB9)

- One CAN FD transceiver has extra 3-pin screw connector terminal

- Single 3.3V supply

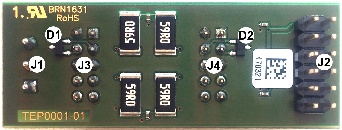

Main Components

J1. Screw connector terminal of CAN0 bus

J2. 2.54mm pitch 2x6-pin header Pmod interface

J3. 2.54mm pitch 2x5-pin box header, CAN0 bus

J4. 2.54mm pitch 2x5-pin box header, CAN1 bus

J5. 2.54mm pitch SMT 2x3-pin jumper block, can also be used as CAN1 bus connector

J6. 2.54mm pitch SMT 2x3-pin jumper block, can also be used as CAN0 bus connector

U1. Texas Instruments TCAN337G CAN FD transceiver, CAN0

D1. Bourns CDSOT23-T24CAN CANbus Protector, CAN0

U2. Texas Instruments TCAN337G CAN FD transceiver, CAN1

D2. Bourns CDSOT23-T24CAN CANbus Protector, CAN1

REV 01 PCB's have the PMOD connector mounted for Right Angle connection to PMOD Baseboard.

Interfaces and Pins

J1 Connector, CAN0 Bus

| Pin | Signal | Notes |

|---|---|---|

| 1 | CAN0_P | U1 high level CAN bus line |

| 2 | GND | U1 ground connection |

| 3 | CAN0_N | U1 low level CAN bus line |

J2 Connector, Pmod Interface

| Pin | Signal | Notes | Pin | Signal | Notes | |

|---|---|---|---|---|---|---|

| 1 | CAN0_TX | U1 CAN0 transmit data input, integrated pull up | 2 | CAN1_TX | U2 CAN1 transmit data input, integrated pull up | |

| 3 | CAN0_RX | U1 CAN0 receive data output, tri-state | 4 | CAN1_RX | U2 CAN1 receive data output, tri-state | |

| 5 | CAN0_S | U1 silent mode,integrated pull down | 6 | CAN1_S | U2 silent mode, integrated pull down | |

| 7 | CAN0_F | U1 open drain fault output | 8 | CAN1_F | U2 open drain fault output | |

| 9 | GND | U1 ground connection | 10 | GND | U2 ground connection | |

| 11 | 3.3V | U1 3.3V supply voltage | 12 | 3.3V | U2 3.3V supply voltage |

J3 Connector, CAN0 Bus

| Pin | Signal | Notes | Pin | Signal | Notes | |

|---|---|---|---|---|---|---|

| 1 | N/A | - | 2 | GND | U1 ground connection | |

| 3 | CAN0_N | U1 low level CAN bus line | 4 | CAN0_P | U1 high level CAN bus line | |

| 5 | GND | U1 ground connection | 6 | N/A | - | |

| 7 | N/A | - | 8 | N/A | - | |

| 9 | N/A | - | 10 | N/A | - |

J4 Connector, CAN1 Bus

| Pin | Signal | Notes | Pin | Signal | Notes | |

|---|---|---|---|---|---|---|

| 1 | N/A | - | 2 | GND | U2 ground connection | |

| 3 | CAN1_N | U2 low level CAN bus line | 4 | CAN1_P | U2 high level CAN bus line | |

| 5 | GND | U2 ground connection | 6 | N/A | - | |

| 7 | N/A | - | 8 | N/A | - | |

| 9 | N/A | - | 10 | N/A | - |

J5 Jumper Block/Connector CAN1 bus

Close pins 1-3 and 2-4 with jumpers to enable on-board terminator for CAN1 bus. J5 header can also be used as CAN1 bus connector, refer to table below for pin mapping.

| Pin | Signal | Note | Pin | Signal | Note | |

|---|---|---|---|---|---|---|

| 3 | CAN1_N | U2 low level CAN bus line | 4 | CAN1_P | U2 high level CAN bus line | |

| 5 | GND | U2 ground connection | 6 | GND | U2 ground connection |

J6 Jumper Block/Connector, CAN0 bus

Close pins 1-3 and 2-4 with jumpers to enable on-board terminator for CAN0 bus. J6 header can also be used as CAN0 bus connector, refer to table below for pin mapping.

| Pin | Signal | Note | Pin | Signal | Note | |

|---|---|---|---|---|---|---|

| 3 | CAN0_N | U1 low level CAN bus line | 4 | CAN0_P | U1 high level CAN bus line | |

| 5 | GND | U1 ground connection | 6 | GND | U1 ground connection |

Operating Conditions, Ratings and Dimensions

Recommended Operating Conditions

| Minimum | Maximum | Unit | |

|---|---|---|---|

| Supply voltage | 3 | 3.6 | V |

| Operational free-air temperature | -40 | 125 | °C |

Absolute Maximum Ratings

| Parameter | Minimum | Maximum | Unit |

|---|---|---|---|

| Supply voltage range | -0.3 | 5 | V |

| Voltage at any bus terminal (CANH or CANL) | -14 | 14 | V |

| Operating temperature range | -40 | 150 | °C |

| Storage temperature | - | 150 | °C |

Refer to Texas Instruments TCAN337G product datasheet for additional information about conditions and ratings.

Power Requirements

3.3V supply voltage TBD* (180 mA max per one CAN FD transceiver in "Normal Mode", dominant state with bus fault as per TCAN337G datasheet).

* TBD - To Be Determined soon with reference design setup.

Physical Dimensions

Module size: 54 mm × 20.5 mm.

Mating height of the J2 connector from the PCB: 8mm

PCB thickness: 1.6mm

Highest parts on PCB are J1, J3 and J4 connectors, approximately 9.5mm from the PCB.

Document Change History

Date | Rrevision | Contributors | Description |

|---|---|---|---|

| 05.09.2016 | Initial document. |

Hardware Revision History

| Date | Revision | Notes | PCN |

|---|---|---|---|

| 22.08.2016 | 01 | Initial batch | - |

Hardware revision number is printed on the PCB board next to the module model number separated by the dash.