Table of Content

Power and Signal Pin Assignment

How to Use This Guide

- This guide is split into two tables:

- Module Power Connection Table section shows the power source of the different FPGA banks and components of the different module boards as well as the power and group location on the B2B connectors of the module site.

Carrier Board Power Connection Table section shows the power source of the B2B connectors with pins, schematic names and available options of the different carrier boards as well as the power location on the B2B connectors of the carrier site.

- The PCBs have fixed and variable user supplied I/O voltage pins. Variable power supply pins are colored in four groups (VCCIOA, VCCIOB, VCCIOC and VCCIOD).

- Find your module model on the Module Power Connection Table and check the power supply of the different FPGA banks.

- If the power supply is variable(colored), go to the Carrier Board Power Connection Table and see how it's connected on your carrier board. Often the power source can be selected by jumper, resistor or variable used from other connector pin of the carrier board. So use the schematic name or the component designator from the table to search for the available options in the PCB schematics or TRM.

- Additional Master Pinout Viewer/XDC-Generator is available on Trenz Electronic Download - Pinout

Module Power Connection Table

| Group | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | special | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module Model | Bank | IOs | Type | Voltage | Bank | IOs | Type | Voltage | Bank | IOs | Type | Voltage | Bank | IOs | Type | Voltage | Bank | IOs | Type | Voltage | Bank | IOs | Type | Voltage | Bank | IOs | Type | Voltage | |||

| TE0710 | B15 | 48 | HR | VCCIOA | - | - | - | - | - | - | - | - | B34 | 50 | HR | VCCIOD | B16 | 6 | HR | 3.3V | B14 | 8 | HR | 3.3V | 2x 100Mbit ETH | ||||||

| TE0711 | B15 | 48 | HR | VCCIOA | B34 | 36 | HR | VCCIOB | B14 | 18 | HR | 3.3V | B35 | 50 | HR | VCCIOD | B16 | 6 | HR | 1.8V | B14 | 8 | HR | 3.3V | B34 | 8 | HR | VCCIOB | B34(4) | USB | |

| TE0712 | B16 | 48 | HR | VCCIOA | B13 | 20 | HR | VCCIOB | B14 | 18 | HR | 3.3V | B15 | 50 | HR | VCCIOD | B13 | 6 | HR | VCCIOB | B14 | 8 | HR | 3.3V | 1x 100Mbit ETH / B13 | 4 | HR | VCCIOB | B14 | 4x GTP on G2 | |

| TE0713 | 4x GTP on G2 | ||||||||||||||||||||||||||||||

TE0715 | B13 | 48 | HR | VCCIOA | B34 | 16 | HR | VCCIOC | B34 | 18 | HR | VCCIOC | B35 | 50 | HR | VCCIOD | B501 | 6 | MIO | 1.8V | B500 | 8 | MIO | 3.3V | 1x Gbit ETH | SGMII | USB | 4x GTP on G2 | |||

| TE0715 with Z-7030 | B13 | 48 | HR | VCCIOA | B34 | 16 | HP | VCCIOC | B34 | 18 | HP | VCCIOC | B35 | 50 | HP | VCCIOD | B501 | 6 | MIO | 1.8V | B500 | 8 | MIO | 3.3V | 1x Gbit ETH | SGMII | USB | 4x GTP on G2 | |||

| TE0720 | B35 | 48 | HR | VCCIOA | B34 | 36 | HR | VCCIOB | B33 | 18 | HR | VCCIOC | B13 | 50 | HR | VCCIOD | B501 | 6 | MIO | 1.8V | B500 | 8 | MIO | 3.3V | 1x Gbit ETH | SGMII | USB | ||||

| TE0820* | B66 | 48 | HP | VCCIOA | B65 | 16 | HP | VCCIOC | B65 | 18 | HP | VCCIOC | B64 | 50 | HP | VCCIOD | B501 | 6 | MIO | 3.3V | B501 | 8 | MIO | 3.3V | 1x Gbit ETH | SGMII | USB | 4x GTR on G2 | |||

| TE0821* | B26 | 48 | HD | VCCIOA | B65 | 16 | HP | VCCIOC | B65 | 18 | HP | VCCIOC | B24 | 48 | HD | VCCIOD | B501 | 6 | MIO | 3.3V | B501 | 8 | MIO | 3.3V | 1x Gbit ETH | SGMII | USB | 4x GTR on G2 | |||

| TE0823* | B66 | 48 | HP | VCCIOA | B65 | 16 | HP | VCCIOC | B65 | 18 | HP | VCCIOC | B64 | 50 | HP | VCCIOD | B501 | 6 | MIO | 3.3V | B501 | 8 | MIO | 3.3V | 1x Gbit ETH | SGMII | USB | 4x GTR on G2 | |||

| TE0741 | B13 | 48 | HR | VCCIOA | B16 | 16 | HR | VCCIOB | B15 | 18 | HR | VCCIOC | B12 | 50 | HR | VCCIOD | 1x GTX | 1 Lane | B14 | 8 | HR | 3.3V | 2x GTX | 2 Lanes | 1x GTX | 4x GTX on G2 | |||||

| TE0742* | |||||||||||||||||||||||||||||||

| TE0841 | B64 | 48 | HR | VCCIOA | B66 | 16 | HP | VCCIOB | B68 | 18 | HP | VCCIOC | B67 | 50 | HP | VCCIOD | 1x GTH | 1 Lane | B65 | 8 | HR | 3.3V | 2x GTH | 2 Lanes | 1x GTH | 4x GTH on G2 | |||||

| TE0842* | |||||||||||||||||||||||||||||||

I/O resource comparison for all 4x5 modules. There are maximum 4 user supplied I/O voltages (VCCIOA, VCCIOB, VCCIOC and VCCIOD).

*Attention: Maximum supply voltage for HP banks is 1.8V.

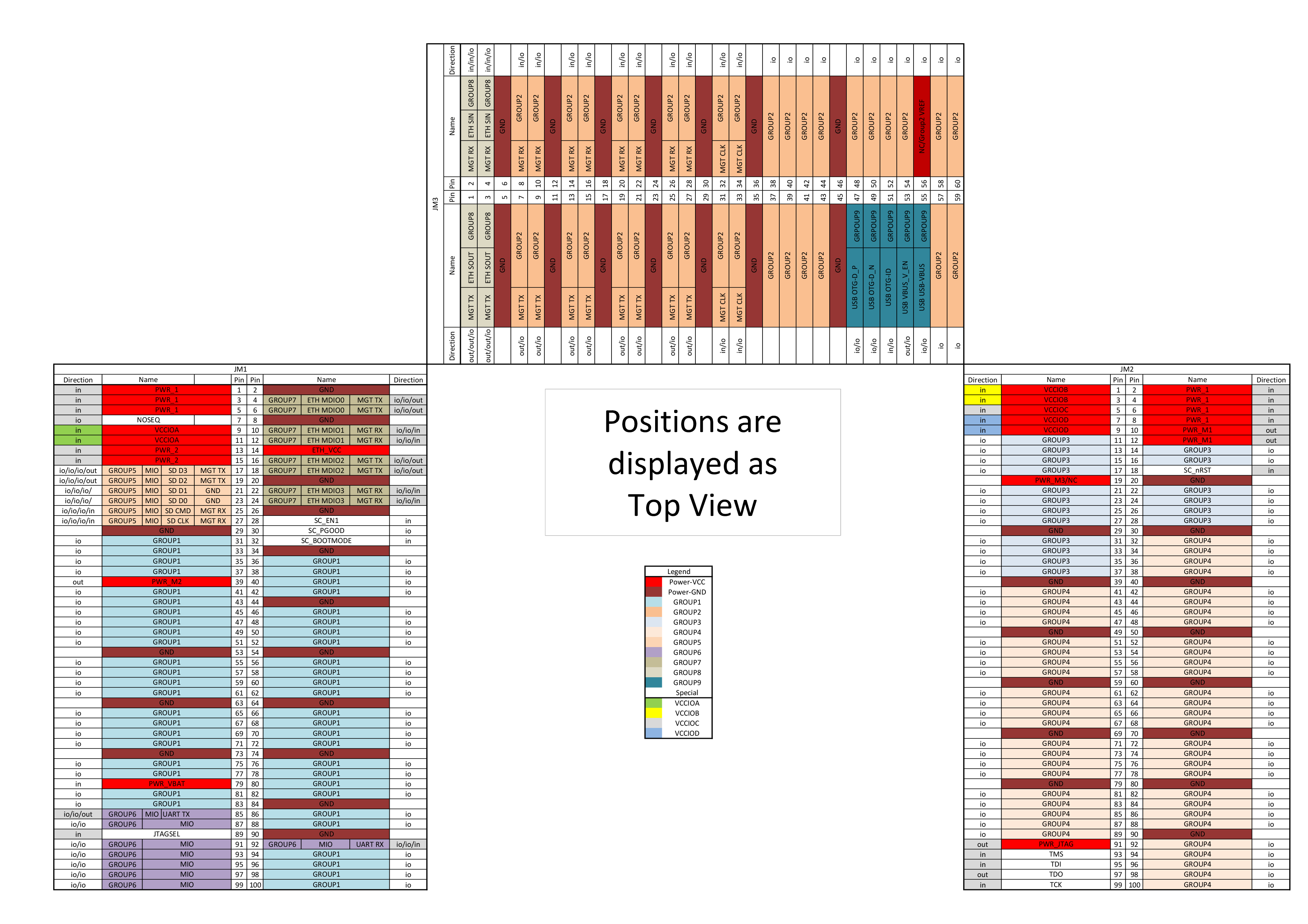

Module Pinout Overview

Carrier Board Power Connection Table

| IO Voltage | B2B Connector | Carrier Boards | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Direction* | JB1 | JB2 | TE0701 | TE0703 Rev01 - Rev04 | TE0703 Rev 05 | TE0705 | TE0706 | TEBA0841 | TEBA0841 REV01 | |||||||

| Pin | Pin | Schematic Name | Value,Option,Comp. | Schematic Name | Value,Option,Comp. | Schematic Name | Value,Option,Comp. | Schematic Name | Value,Option,Comp. | Schematic Name | Value,Option,Comp. | Schematic Name | Value,Option,Comp. | Schematic Name | Value,Option,Comp. | ||

| PWR_1 | out | 2,4,6 | 1,3,5,7 | 5V0 | 5V | 3.3V | 3.3V | 3.3V | 3.3V | 5V0 | 5V | 3.3V | 3.3V | 3.3V | use ext. 3.3V power supply | 3.3V | use ext. 3.3V power supply |

| VCCIOA | out | 10,12 | VIOTB | FMC_VADJ 2V5 3.3VOUT | VCCIO35 | R23→M3.3VOUT J1B-B1 | VCCIOA | J5→M3.3VOUT, M1.8VOUT R23→M3.3VOUT J1-B1 | VIOTB | FMC_VADJ 2V5 3.3VOUT | VCCIO35 | R20->M3.3VOUT/J6B-B32 | VCCIOA | J26→ M1.8VOUT, 2.5V, 3.3V_OUT J20-6,J20-45 | VCCIOA | J26→ M1.8VOUT, 2.5V, 3.3V_OUT J20-6,J20-45 | |

| VCCIOD | out | 8,10 | VIOTB | FMC_VADJ 2V5 3.3VOUT | VCCIO13 | R26→M3.3VOUT J2B-B1 | VCCIOD | J10→M3.3VOUT, M1.8VOUT R26→M3.3VOUT J2B-B1 | VIOTB | FMC_VADJ 2V5 3.3VOUT | VCCIO13 | R22->M3.3VOUT/J6B-B1 | VCCIOD | J27→ M1.8VOUT, 2.5V, 3.3V_OUT J17-6,J17-45 | VCCIOD | J27→ M1.8VOUT, 2.5V, 3.3V_OUT J17-6,J17-45 | |

| PWR_2 | out | 14,16 | 3V3IN | 3.3V | 3.3V | 3.3V | 3.3V | 3.3V | 3V3IN | 3.3V | 3.3V | 3.3V | 3.3V | use ext. 3.3V power supply | 3.3V | use ext. 3.3V power supply | |

| VCCIOB | out | 2,4 | no name / VIOTA | FMC_VADJ 2V5 3.3VOUT | VCCIO34 | J5→M3.3VOUT J1B-B32 | VCCIOB | J8→M3.3VOUT,M1.8VOUT J2B-B32 | VIOTB | FMC_VADJ 2V5 3.3VOUT | 1.8V | 1.8V | VCCIOB | J5→ M1.8VOUT, 2.5V, 3.3V_OUT | VCCIOB | NC | |

| VCCIOC | out | 6 | no name / VIOTA | FMC_VADJ 2V5 3.3VOUT | VCCIO33 | R25→M3.3VOUT J2B-B32 | VCCIOC | J9→M3.3VOUT, M1.8VOUT R25→M3.3VOUT J2B-B32 | VIOTB | FMC_VADJ 2V5 3.3VOUT | VCCIO33 | R21->M3.3VOUT | VCCIOC | J6→ M1.8VOUT, 2.5V, 3.3V_OUT | VCCIOC | NC | |

| PWR_M1 | in | 9,11 | 3.3VOUT | 3.3V | 3.3VOUT | 3.3V | M3.3VOUT | 3.3V | 3.3VOUT | 3.3V | M3.3VOUT | 3.3V | 3.3V_OUT | 3.3V | 3.3V_OUT | 3.3V | |

| PWR_M2 | in | 40 | VIOB | 1.8V | M1.8VOUT | 1.8V | M1.8VOUT | 1.8V | VIOB | 1.8V | M1.8VOUT | 1.8V | M1.8VOUT | 1.8V | M1.8VOUT | 1.8V | |

| PWR_M3 | in | 20 | NC | NC | NC | NC | NC | NC | NC | ||||||||

| PWR_VBAT | out | 80 | VBAT | B1 | VBAT | J7 | VBAT | J7 | NC | VBAT | J9 | VBAT | NC | VBAT | NC | ||

PWR_JTAG | in | 92 | VCCJTAG | VCCJTAG | VCCJTAG | VCCJTAG | VCCJTAG | VCCJTAG | VCCJTAG | NC | |||||||

Power comparison of all 4x5 carrier boards. *Power direction based on carrier boards view.There are 4 variable user supplied I/O voltages (VCCIOA, VCCIOB, VCCIOC and VCCIOD). PWR_1 and PWR_2 are fixed from carrier boards. PWR_M1 and PWR_M2 normally use default value from module. NC=Not Connected

Attention: On some carrier boards the user supplied I/O voltages are connected together (red colored schematic names).

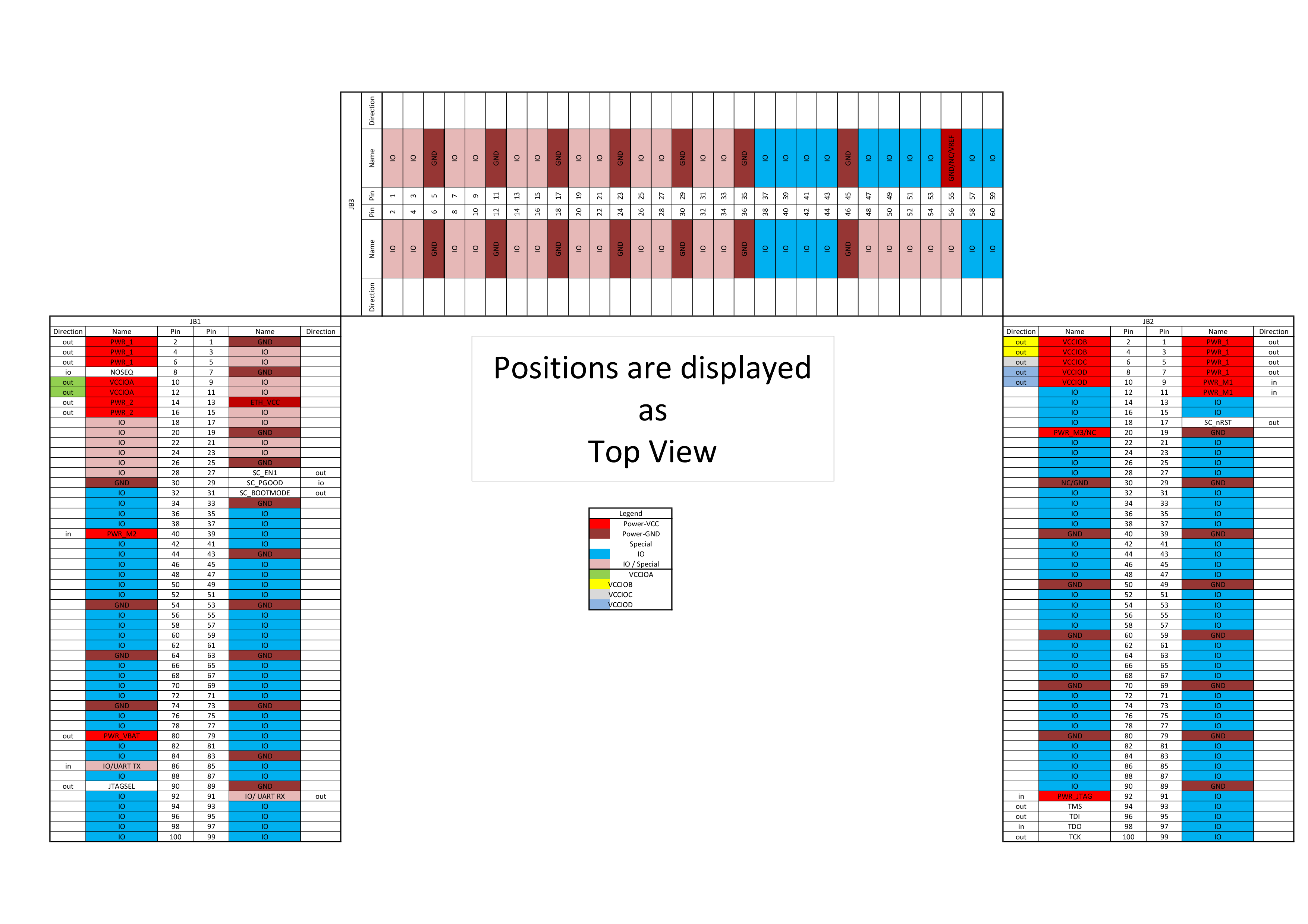

Carrier Pinout Overview

4x5 Module Controller IOs

| Name | Module B2B Pin | Carrier B2B Pin | Direction (Module view) | Description | Recommendation |

|---|---|---|---|---|---|

| JTAGSEL | JM1-89 | JB1-90 | in | JTAG Chain multiplexer. Low FPGA, High CPLD. For module with CPLD only. | Connect Pulldown on carrier. |

| SC_EN1 | JM1-28 | JB1-27 | in | Module power. Set high to enable module power. Note: Power management depends on module. Sometimes this is a only used as Power ON Reset like SC_nRST | Connect Pullup on carrier. DIP switch possible |

| SC_NOSEQ | JM1-7 | JB1-8 | in / inout | Module Power management. Set high to disable CPLD power management. Note: Power management depends on module and not all modules support extended power management with CPLD. | Connect Pullup or force to GND over zero ohm resistor on carrier. DIP switch possible. |

| SC_PGOOD | JM1-30 | JB1-29 | out / inout | Power Good signal. Is Low, if SC_EN1 is set to zero or if power is not ready, otherwise high impedance output. Note: Power management depends on module. On newer Firmware SC_PGOOD will be used as Additionally Boot Mode Pin. | Connect Pullup on carrier. Do not use this signal to enable FPGA Bank voltages. It's only for monitoring. To Enable FPGA Banks, use 3.3V(PWR_M1) or 1.8V(PWR_M2) module output. |

| SC_BOOTMODE | JM1-32 | JB1-31 | in | Boot Mode selection Pin for Zynq module only. Default low for primary SD boot and high for primary QSPI boot. Note: Depends also on module CPLD firmware | Connect Pullup on carrier. DIP switch possible. |

| SC_nRST | JM2-18 | JB2-17 | in | Low active module reset. Pin force Power one reset on FPGA/SoC. Note: Depending from module CPLD or voltage supervisor is used. | Connect Pullup on carrier. DIP switch possible. |

- Controller IOs are 3.3V IOs

It's planned to use SC_PGOOD also as additional Boot Mode Pin (Pin is bidirectional, pull up or force to zero), to additionally set JTAG only boot mode (to avoid programming problems with some vivado versions, see: AR#00002 - QSPI Programming issues). Current state of CPLD Redesigns: AVN-20220506 4 x 5 modules controller IOs redefinition and CPLD updates

Remove 4x5 module

4 x 5 SoMs Handling and Usage Precautions

Compatibility Guide

Ethernet LED'S

TE07xx 4x5 modules do not have dedicated pins for the Ethernet PHY LED's, also there are no fix pins on the baseboards for the PHY LED's or any other LED's.

If Ethernet JACKs on Baseboard have LED's then those should be connected to some free PL I/O pins, and then routed in the FPGA logic from the PHY to the I/O Pin in the B2B Connector.

Recommended connections would be to use JM2.89 and JM2.100 for the PHY LED's, those positions support baseboard ETH LED's for TE0701 and TE0703 and TE0706.

JM2 pins 1, 3 (TE0720 Bank 34 Voltage)

To be compatible with TE0720 JM2 pins 1,3 must be connected to some valid VCCIO voltage.

When JM2 pins 1, 3 are not powered TE0720 would not boot, and may not be recognized in JTAG chain as well.

When those pins are not used on the module (TE0710) then to be compatible with TE0720:

Solution A: connect to 3.3V out from the module, option compatible to all modules except those with HP banks

Solution B: connect to 1.8V out from the module, option compatible with all modules.

Carrier Board Checklist

Schematic Checklist

| 1 | Are B2B pin numbers on the connectors mirrored compared to the module pin numbers? | As B2B connectors are "unisex" type the do mirror pin numbers when connecting. That is pin1 connects to pin2, and pin2 to pin1, etc. |

| 2 | Are B2B connectors named JB1, JB2, JB3? | This is not a hard requirement, but it helps to use the same identifiers. |

| 3 | Are all GND pins connected to a common ground net? | |

| 4 | Are all VIN pins connected together? | |

| 5 | Is JB2 pin 92 pin used as VREF for the JTAG interface? | for future compatibility only, currently all modules have 3.3V JTAG |

| 6 | For 7 Series Zynq module only: Are external circuits/buffers connecting to MIO bank 1 pins powered from JB1 pin 40? | JB1 pins 18, 20, 22, 24, 26, 28 use voltage at pin 40 as VCCIO. Currently it is 1.8V for 4x5 Zynq Modules. Note: Different Power supply on TE0820(3.3V MIO Bank) and normal FPGA modules(check schematics) |

PCB Checklist

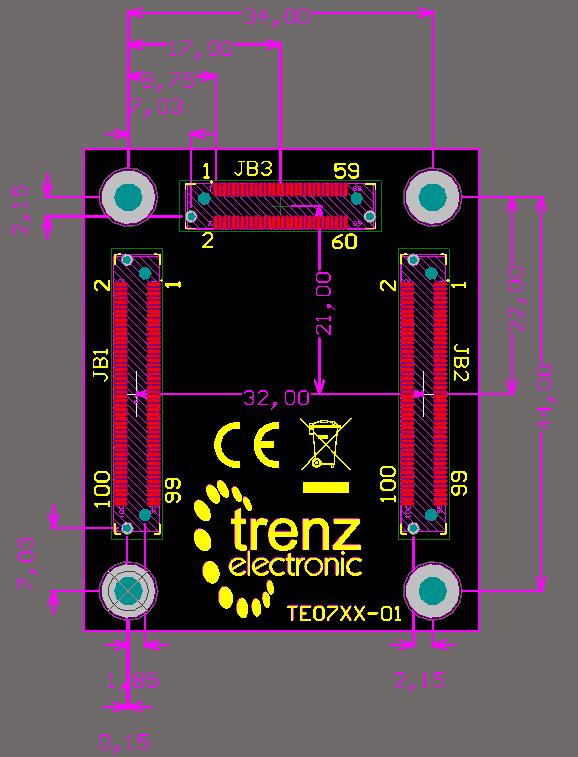

| 1 | Are mounting holes placed properly? | Four Mounting holes should always be used. They are required for mounting screws and for module extraction. The mounting holes will also help in dissipating some heat from the module to the carried board PCB. Four holes with a 3.2mm diameter should be placed exactly at the corners of a 34mm by 44mm rectangle. |

| 2 | Are B2B headers properly placed? | B2B headers must be placed and aligned very precisely or the module will not align correctly (in the worst case module insertion could destroy the connectors or the PCB). The B2B headers should be locked on the PCB, and it is recommended that the position and placement be checked against placement dimensions before submitting the PCB files. |

| 3 | Are B2B headers rotated properly? | As B2B header pin numbers differ from module to the carrier (swap of odd and even numbers), it is recommended that the rotation is checked in the PCB design. |

| 4 | Height clearance below module | Components can be placed below the module but height clearance rules must be obeyed. |

| 5 | Power dissipation of components below module | It is not recommended to place any components with high power dissipation below the module, as there will be almost no airflow below the module. |

Visual Check of Module placement

It is highly recommended to use the Base board Template designs as a starting point for new PCB designs. If that is not possible, then adding linear dimensions in the design helps to check that all connectors and mounting holes are properly placed.

This placement is same for all 4x5 Modules!

Top view of the Carrier Board.

Connector numbers as on base! (pin JB1.1 on base would mate to pin JM1.2 on module).