Table of Contents

Overview

The Trenz Electronic TEM0002-01 SmartBerry with Raspberry Pi form factor, is an industrial-grade module based on Microsemi SmartFusion2 SoC (System on a Chip). The Module has 128MB DDR3 SDRAM, a Gigabit Ethernet PHY, four PMODs, a GPIO Pin header compatible to the Raspberry Pi pinout and a Micro USB to UART interface. SmartFusion2 combines a 166 MHz Cortex-M3 core with 256 KByte Flash, 80 KByte SRAM and a 12 kLUT FPGA core logic.

Key Features

- Microsemi SmartFusion2 SoC FPGA (M2S010)

- 128 MByte DDR3 SDRAM

- On board power converters for all needed voltages

- 40 pin header (compatible to Raspberry Pi pinout)

- 4 x 12 pin PMODs

- Gigabit Ethernet PHY with RGMII interface

- JTAG and UART via Micro USB

- 3 pin header for Live Probes

- 2 x User Button

- 2 x status LED

- 1 x RGB LED

Additional assembly options are available for cost or performance optimization upon request.

Block Diagram

Figure 1: TEM0002-01 block diagram.

Main Components

Figure 2: TEM0002-01 main components.

- Microsemi SmartFusion2 SoC FPGA, U2

- USB to UART/FIFO (FTDI FT2232H), U3

- Gigabit ETH connector, J2

- 4x 2x6 pin PMOD, P1, P2, P3, P4

- GPIO pin header compatible to Raspberry Pi, J8

- Micro USB 2.0, J1

- EEPROM 4KBIT (M93C66-R), U6

- 2x User Button, S4, S5

- RGB LED, D3

- LED red, D1 and green, D2

- Live Probe pins, J4

- Reset jumper, J13

- JTAG select jumper, J6

- Board power header, J5

- 1Gb DDR3/L SDRAM, U5

- MicroSD memory card connector, J3

- Gigabit Ethernet PHY, U1

Initial Delivery State

Storage device name | Content | Notes |

|---|---|---|

| Microsemi SmartFusion2 SoC FPGA, U2 | Demo Design | - |

| EEPROM, U6 | Programmed | FTDI (FT2232H) configuration data. |

Table 1: Initial delivery state of programmable devices on the module.

Boot Process

The SmartBerry supports

Signals, Interfaces and Pins

I/Os

I/O signals provided on the Rasperry Pi compatible header are connected to bank 2 of the Microsemi SoC.

| I/O Signal Count | Bank Voltage | Notes |

|---|---|---|

| 26 I/Os | 3.3V |

Table 2: General overview of I/O signals connected to the SoC.

Further I/Os are provided via the PMOD connectors descriebed below.

PMODs

The module provides four 2x6 female PMOD connectors. Two of the headers (P2 and P3) are arranged to use as dual 12 pin PMOD. According to the standard on all four headers Pin 5 and 11 are connected to ground, 6 and 12 to 3.3V.

| FPGA SoC Signal | Pin | PMOD Signal | PMOD Pin |

|---|---|---|---|

| MSIO71PB7 | U2-F3 | PB-01 | P1-1 |

| MSIO71NB7 | U2-F4 | PB-02 | P1-2 |

| MSIO68NB7 | U2-E3 | PB-03 | P1-3 |

| MSIO80NB7 | U2-H4 | PB-04 | P1-4 |

| MSIO75PB7 | U2-G4 | PB-05 | P1-7 |

| MSIO70PB7 | U2-E1 | PB-06 | P1-8 |

| MSIO67NB7 | U2-E5 | PB-07 | P1-9 |

| MSIO78NB7 | U2-G3 | PB-08 | P1-10 |

| MSIO79PB7 | U2-G1 | PC-01 | P2-1 |

| MSIO79NB7 | U2-F1 | PC-02 | P2-2 |

| MSIO70NB7 | U2-E2 | PC-03 | P2-3 |

| MSIO64PB7 | U2-C1 | PC-04 | P2-4 |

| MSIO78PB7 | U2-G2 | PC-05 | P2-7 |

| MSIO70PB7 | U2-E1 | PC-06 | P2-8 |

| MSIO68PB7 | U2-D2 | PC-07 | P2-9 |

| MSIO64NB7 | U2-C2 | PC-08 | P2-10 |

| MSIO117NB4 | U2-Y16 | PA-01 | P3-1 |

| MSIO117PB4 | U2-Y15 | PA-02 | P3-2 |

| MSIO112PB4 | U2-W13 | PA-03 | P3-3 |

| MSIO110PB4 | U2-V12 | PA-04 | P3-4 |

| MSIO118PB4 | U2-W15 | PA-05 | P3-7 |

| MSIO112NB4 | U2-W14 | PA-06 | P3-8 |

| MSIO105NB4 | U2-Y13 | PA-07 | P3-9 |

| MSIO105NB4 | U2-Y13 | PA-08 | P3-10 |

| MSIO4PB2 | U2-P20 | PD-01 | P4-1 |

| MSIO3NB2 | U2-R20 | PD-02 | P4-2 |

| MSIO2NB2 | U2-T19 | PD-03 | P4-3 |

| MSIO0PB2 | U2-V20 | PD-04 | P4-4 |

| MSIO6NB2 | U2-P19 | PD-05 | P4-7 |

| MSIO3PB2 | U2-T20 | PD-06 | P4-8 |

| MSIO1NB2 | U2-U19 | PD-07 | P4-9 |

| MSIO0NB2 | U2-V19 | PD-08 | P4-10 |

JTAG Interface

JTAG access to the SoC components is provided through the micro usb connector via the FTDI usb to UART bridge. Depending on the jumper J6 the JTAGSEL signal SW3 switches the JTAG interface to either the FPGA fabric TAP (OPEN, high) or the Cortex-M3 JTAG debug interface (CLOSED, low). JTAG signals are powered by 3.3V.

FTDI signal | pin | JTAG Signal | Microsemi SmartFusion2 SoC pin |

|---|---|---|---|

| ADBUS0 | U3-12 | TCK | U2-W19 |

| ADBUS1 | U3-13 | TDI | U2-V16 |

| ADBUS2 | U3-14 | TDO | U2-Y20 |

| ADBUS3 | U3-15 | TMS | U2-V17 |

Table 5: JTAG interface signals.

SD Card Interface

The SD Card interface is connected to Bank 2 of the SoC

| FPGA / SoC Pin | Connected To | Signal Name | Notes |

|---|---|---|---|

| U2-H16 | J3-9 | SD_CD | Card detect switch |

| U2-N15 | J3-7 | SD_D0 | |

| U2-G18 | J3-8 | SD_D1 | |

| U2-R16 | J3-1 | SD_D2 | |

| U2-R17 | J3-2 | SD_D3 | |

| U2-R15 | J3-3 | SD_CMD | |

| U2-P15 | J3-5 | SD_CLK |

Table 6: SD Card interface signals and connections.

Ethernet Interface

| PHY Pin | Signal | Microsemi SmartFusion2 SoC signal | Pin | Notes |

|---|---|---|---|---|

| U1-25 | ETH_TXCK | MSIOD84PB6 | U2-K7 | |

| U1-23 | ETH_TXCTL | MSIOD87NB6 | U2-K3 | |

| U1-26 | ETH_TXD0 | MSIOD93PB6 | U2-L1 | |

| U1-28 | ETH_TXD1 | MSIOD97NB6 | U2-M2 | |

| U1-29 | ETH_TXD2 | MSIOD97PB6 | U2-M1 | |

| U1-30 | ETH_TXD3 | MSIOD95PB6 | U2-M3 | |

| U1-22 | ETH_RRXCK | MSIOD84PB6 | U2-J2 | |

| U1-21 | ETH_RRXCTL | MSIOD93NB6 | U2-K1 | |

| U1-20 | ETH_RRXD0 | MSIOD86PB6 | U2-K5 | |

U1-18 | ETH_RRXD1 | MSIOD82PB6 | U2-H1 | |

| U1-17 | ETH_RRXD2 | MSIOD82NB6 | U2-H2 | |

| U1-16 | ETH_RRXD3 | MSIOD83PB6 | U2-J4 | |

| U1-31 | ETH_MDC | MSIOD99PB6 | U2-N1 | |

| U1-33 | ETH_MDIO | MSIOD99NB6 | U2-N2 | |

| U1-34 | ETH_MDINT | MSIOD98PB6 | U2-N4 | |

| U1-35 | ETH_RST | MSIO114PB4 | U2-R13 | |

| U1-36 | PHY_RCLKOUT | MSIO102NB4/CCC_NE1_CLKIO | U2-W10 | |

| U1-39 | PHY_LED0 | MSIO104NB4 | U2-U11 | |

| U1-38 | PHY_LED1 | MSIO116PB4 | U2_T14 |

Table 7: Ethernet PHY signals and connections.

I2C Interface

There are no on-board I2C devices. For Raspberry Pi compability the device detection I2C bus is routed from the header J8-27/28 to Bank 1 U2-A20/A19 (SDA/SCL).

| I2C Device | I2C Address | Notes |

|---|---|---|

| Header J8 | 0x50 | Device detection/identification. |

Table 8: I2C slave device addresses.

On-board Peripherals

DDR Memory

TEM0002 has 1Gb industrial grade DDR3 SDRAM (U5). A 16-bit wide memory bus providing total of 128 MBytes of on-board RAM. Specification is 800 MHz clocking resulting in 1600 Mb/s data rate and timings of 11-11-11 (CL-TRCD-TRP).

Gigabit Ethernet PHY

On-board Gigabit Ethernet PHY (J2) is provided by Microsemi VSC8531 chip (U1). The Ethernet PHY RGMII interface is connected to Bank 6 of the Microsemi SOC. I/O voltage is fixed at 1.5V. The reference clock input of the PHY is supplied from an external 25.000000 MHz oscillator (U11).

Oscillators

The module has following reference clock signals provided by on-board oscillators:

| Clock Source | Schematic Name | Frequency | Clock Destination |

|---|---|---|---|

| Crystal CX3225CA25000D0HSSCC | Y1 | 25.000 MHz | SmartFusion2 SoC U2 Main XTAL |

| Crystal ECX-31B | Y2 | 32.768 KHz | SmartFusion2 SoC U2 AUX XTAL |

| SiTime SiT8008AI oscillator | U11 | 25.000000 MHz | Gb Ethernet Copper PHY U1A |

| SiTime SiT8008AI oscillator | U14 | 25.000000 MHz | SmartFusion2 SoC U2-Y12 Bank 4 |

Table 9: Reference clock signals.

In REV02, Y1 will be replaced by a 12 MHz crystal.

On-board LEDs

| LED | Color | Connected to | Description and Notes |

|---|---|---|---|

| D1 | Red | U2-G16 Bank 1 | |

| D2 | Green | U2-G17 Bank 1 | |

| D3 | RGB | U2-H5 Bank 7, U2-F6 Bank 7, U2-H6 Bank 7 | |

| J2 | Green, Yellow | U2-Y10 Bank 4, U2-U12 Bank 4 | Ethernet: LED1A, LED1B |

| J2 | Green, Yellow | U2-V14 Bank 4, U2-U14 Bank 4 | Ethernet: LED2A, LED2B |

Table 10: On-board LEDs.

Power and Power-On Sequence

There is no specific power on Sequence. Just supply with 5V via the micro USB J1 or the J5 PWR_IN with current rating sufficient for your Design.

Power Consumption

The maximum power consumption of a module mainly depends on the design running on the FPGA.

| Power Input | Typical Current |

|---|---|

| VIN | TBD* |

| 3.3VIN | TBD* |

Table 11: Typical power consumption.

* TBD - To Be Determined soon with reference design setup.

Power supply with minimum current capability of ...A for system startup is recommended.

For the lowest power consumption and highest efficiency of the on-board DC-DC regulators it is recommended to power the module from one single 3.3V supply. All input power supplies have a nominal value of 3.3V. Although the input power supplies can be powered up in any order, it is recommended to power them up simultaneously.

Power Distribution Dependencies

Figure 3: Module power distribution diagram.

Power Rails

Power Rail Name | Connector pin | Direction | Notes |

|---|---|---|---|

| VIN | J5-1 | Input | Main supply voltage. |

| 5V | J8-2, J8-4 | Output | |

| 3.3V | J8-1, J8-17 | Output | |

| 1.5V | - | Output | |

1.2V | - | Output | |

| GND | J5-2, J8-9/25/39/6/14/20/30/34 |

Table 12: Module power rails.

Bank Voltages

Bank | Schematic Name | Voltage | Voltage Range |

|---|---|---|---|

| 0 (DDR3) | 1.5V | 1.5V | - |

| 1 | 3.3V | 3.3V | - |

| 2 | 3.3V | 3.3V | - |

| 3 | 3.3V | 3.3V | - |

| 4 | 3.3V | 3.3V | - |

| 5 | 1.5V | 1.5V | - |

| 6 | 1.5V | 1.5V | - |

| 7 | 3.3V | 3.3V | - |

Table 13: I/O bank voltages.

Board to Board Connectors

Variants Currently In Production

NB! Note that here we look at the module as a whole, so you just can't rely only on junction temperature or max voltage of particular SoC or FPGA chip on the module. See examples in the table below.

| Module Variant | FPGA / SoC | Operating Temperature | Temperature Range |

|---|---|---|---|

| TEM0002-01 | M2S010 | 0°C to +85°C | commercial |

Table : Module variants.

Technical Specifications

Absolute Maximum Ratings

Parameter | Min | Max | Units | Reference Document |

|---|---|---|---|---|

VIN supply voltage | V | - | ||

Storage temperature | °C | - |

Table : Module absolute maximum ratings.

Recommended Operating Conditions

| Parameter | Min | Max | Units | Reference Document |

|---|---|---|---|---|

| VIN supply voltage | ||||

| Operating temperature |

Table : Module recommended operating conditions.

Operating Temperature Ranges

Industrial grade: 0°C to +85°C.

Module operating temperature range depends also on customer design and cooling solution. Please contact us for options.

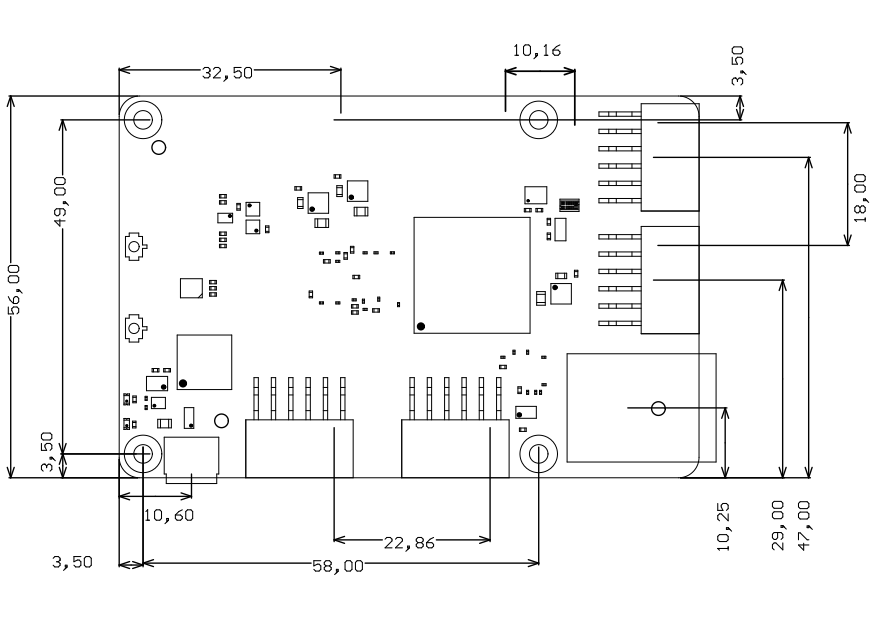

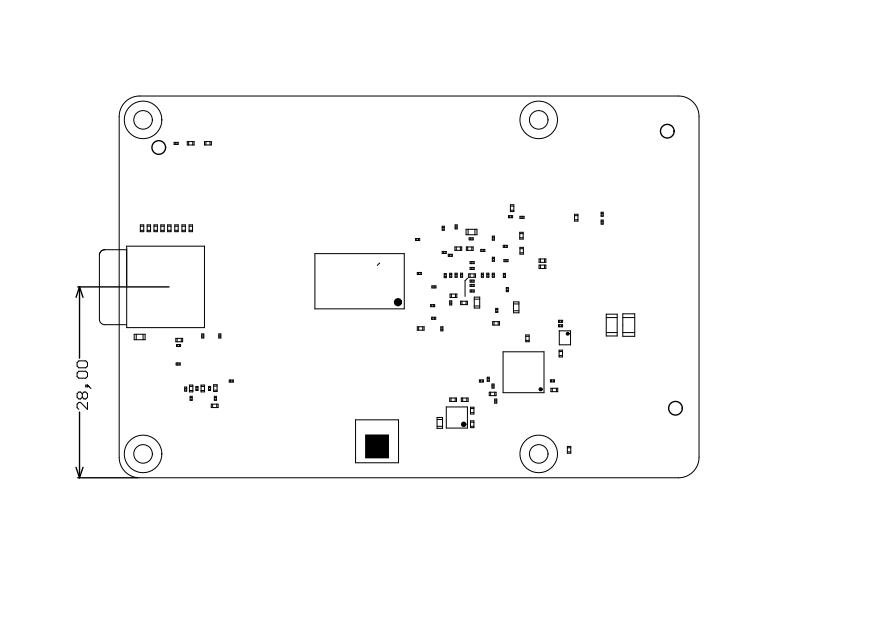

Physical Dimensions

Module size: 85 mm × 56 mm. Please download the assembly diagram for exact numbers.

PCB thickness: 1.55 mm.

Highest part on PCB: top approx. 13.3 mm (Ethernet), bottom 1.57mm (SD-Card)Please download the step model for exact numbers.

All dimensions are given in millimeters.

Figure : Module physical dimensions drawing.

Revision History

Hardware Revision History

| Date | Revision | Notes | PCN | Documentation Link |

|---|---|---|---|---|

| - | 01 | Prototypes |

Table : Module hardware revision history.

Hardware revision number can be found on the PCB board together with the module model number separated by the dash.

Figure : Module hardware revision number.

Document Change History

Date | Revision | Contributors | Description |

|---|---|---|---|

| Under construction. | |||

2017-05-30 | v.1 | Jan Kumann | Initial document. |

all | Jan Kumann, John Hartfiel |

Table : Document change history.

Disclaimer

Data Privacy

Please also note our data protection declaration at https://www.trenz-electronic.de/en/Data-protection-Privacy

Document Warranty

The material contained in this document is provided “as is” and is subject to being changed at any time without notice. Trenz Electronic does not warrant the accuracy and completeness of the materials in this document. Further, to the maximum extent permitted by applicable law, Trenz Electronic disclaims all warranties, either express or implied, with regard to this document and any information contained herein, including but not limited to the implied warranties of merchantability, fitness for a particular purpose or non infringement of intellectual property. Trenz Electronic shall not be liable for errors or for incidental or consequential damages in connection with the furnishing, use, or performance of this document or of any information contained herein.

Limitation of Liability

In no event will Trenz Electronic, its suppliers, or other third parties mentioned in this document be liable for any damages whatsoever (including, without limitation, those resulting from lost profits, lost data or business interruption) arising out of the use, inability to use, or the results of use of this document, any documents linked to this document, or the materials or information contained at any or all such documents. If your use of the materials or information from this document results in the need for servicing, repair or correction of equipment or data, you assume all costs thereof.

Copyright Notice

No part of this manual may be reproduced in any form or by any means (including electronic storage and retrieval or translation into a foreign language) without prior agreement and written consent from Trenz Electronic.

Technology Licenses

The hardware / firmware / software described in this document are furnished under a license and may be used /modified / copied only in accordance with the terms of such license.

Environmental Protection

To confront directly with the responsibility toward the environment, the global community and eventually also oneself. Such a resolution should be integral part not only of everybody's life. Also enterprises shall be conscious of their social responsibility and contribute to the preservation of our common living space. That is why Trenz Electronic invests in the protection of our Environment.

REACH, RoHS and WEEE

REACH

Trenz Electronic is a manufacturer and a distributor of electronic products. It is therefore a so called downstream user in the sense of REACH. The products we supply to you are solely non-chemical products (goods). Moreover and under normal and reasonably foreseeable circumstances of application, the goods supplied to you shall not release any substance. For that, Trenz Electronic is obliged to neither register nor to provide safety data sheet. According to present knowledge and to best of our knowledge, no SVHC (Substances of Very High Concern) on the Candidate List are contained in our products. Furthermore, we will immediately and unsolicited inform our customers in compliance with REACH - Article 33 if any substance present in our goods (above a concentration of 0,1 % weight by weight) will be classified as SVHC by the European Chemicals Agency (ECHA).

RoHS

Trenz Electronic GmbH herewith declares that all its products are developed, manufactured and distributed RoHS compliant.

WEEE

Information for users within the European Union in accordance with Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on waste electrical and electronic equipment (WEEE).

Users of electrical and electronic equipment in private households are required not to dispose of waste electrical and electronic equipment as unsorted municipal waste and to collect such waste electrical and electronic equipment separately. By the 13 August 2005, Member States shall have ensured that systems are set up allowing final holders and distributors to return waste electrical and electronic equipment at least free of charge. Member States shall ensure the availability and accessibility of the necessary collection facilities. Separate collection is the precondition to ensure specific treatment and recycling of waste electrical and electronic equipment and is necessary to achieve the chosen level of protection of human health and the environment in the European Union. Consumers have to actively contribute to the success of such collection and the return of waste electrical and electronic equipment. Presence of hazardous substances in electrical and electronic equipment results in potential effects on the environment and human health. The symbol consisting of the crossed-out wheeled bin indicates separate collection for waste electrical and electronic equipment.

Trenz Electronic is registered under WEEE-Reg.-Nr. DE97922676.