Page History

...

| Interfaces | I/O Signal Count | Pin schematic Names / FMC Pins | Connected to | Notes |

|---|---|---|---|---|

| JTAG | 5 | FMC_TCK, pin J5-D29 FMC_TMS, pin J5-D33 FMC_TDI, pin J5-D30 FMC_TDO, pin J5- D31 | SC CPLD U17, bank 1 | VCCIO: 3V3SB TRST_L, pin J5-D34 pulled-up to 3V3_PER |

| I²C | 2 | FMC_SCL, pin J5-C30 FMC_SDA, pin J5-C31 | I²C - Switch U16 | I²C-lines pulled-up to 3V3_PER |

| Control Lines | 3 | FMC_PRSNT_M2C, pin J5-H2 FMC_PG_C2M, pin J5-D1 (3V3_PER pull-up) FMC_PG_M2C, pin J5-F1 (3V3_PER pull-up) FMC_CLK_DIR, pin J5-B1 (pulled-down to GND) | I²C-Switch U16 via I²C - I/O -Port- Expander U38 SC CPLD U39, bank 0 I²C-Switch U16 via I²C - I/O -Port- Expander U38 SC CPLD U17, bank 1 | 'PG' = 'Power Good'-signal 'C2M' = carrier to (mezzanine) module 'M2C' = (mezzanine) module to carrier |

...

Following table contains the assignment of the MIO pins to the configured interfaces:

| MIO | Configured asAlternate | System Controller CPLD | Notes | |

|---|---|---|---|---|

| 0..12 | Dual QSPI | - | Dual Flash Memory on TE0808 SoM; Bootable | |

| 13..23 | SD0: eMMC | - | eMMC Memory U2; Bootable | |

| 24, 25 | - | CPLD (U39) MUXED | - | |

| 26..29 | PJTAG0- | CPLD (U17 MUXED | Bootable JTAG (PJTAG0) possible | |

| 30 | force reboot after FSBL-PLL config for PCIe - | CPLD (U39) MUXED | - | |

| 31 | PCIe reset | CPLD (U39) MUXED | Same as ZCU102- | |

| 32 | - | CPLD (U39) MUXED | - | |

| 33 | PMU- | CPLD (U39) MUXED | Same as ZCU102- | |

| 34..37 | DisplayPort Aux- | CPLD (U39) MUXED | - | |

| 38, 39 | I2C0 | - | - | |

| 40, 41CAN1 | forwarded to PWRLED_P / LED_P | CPLD (U39) MUXED | - | |

| 41 | - | - | - | |

| 42, 43 | UART0 | CPLD (U39) MUXED | - | |

| 44 | I2C Interrupt | SD_WP to FPGA | CPLD (U39) MUXED | - |

| 45..51 | SD1: SD | - | Bootable MikeoSD MikroSD / MMC Card | |

| 52..63 | USB0 | - | - | |

| 64..75 | GEM3 | - | Ethernet RGMII | |

| 76, 77 | MDC / MDIO | - | Ethernet RGMII |

...

- SATA (PS GT bank 505, MGT2 Lane)

- Display-Port (PS GT bank 505, MGT3 Lane, only TX-pair routed)

- PCI Express (PS GT bank 505, MGT0 Lane)

| Function | MGT Lane | Required Ref Clock | Clock Source | Comment |

|---|---|---|---|---|

| PCIe | PS 0 | 100 MHz | Si5345 (CLK0 of prog. PLL on mounted SoM) | - |

| USB3 | PS 1 | 100 MHz | Optional Oscillator U6 | - |

| SATA | PS 2 | 150 MHz | Oscillator U23 | - |

| DP.0 | PS 3 | 27 MHz- | - | Display Port |

Table 6: PS GT Lane Assignment

...

Figure 4: TEBF0808 PS GT Bank 505 Interface

MGT Interfaces SFP+ and

...

FireFly

The TEBF0808 carrier board provides the high speed MGT interface connectors "SFP+" (Enhanced small form-factor pluggable) and Samtec "FireFly". Each of this connectors are capable of data transmission rates up to 10 Gbit/s.

| Function | MGT Lane | Required Ref Clock | Clock Source | Comment |

|---|---|---|---|---|

| FireFly | B128 MGT Lanes 0..3 | - | - | - |

| SFP | B230 MGT Lane 2 | 125 / 156.25 MHz | Si5345 (CLK7 of prog. PLL on mounted SoM) | - |

| SFP | B230 MGT Lane 3 | 125 / 156.25 MHz | Si5345 (CLK7 of prog. PLL on mounted SoM) | - |

...

| Header | Pin Name | Function | Connected to | Notes |

|---|---|---|---|---|

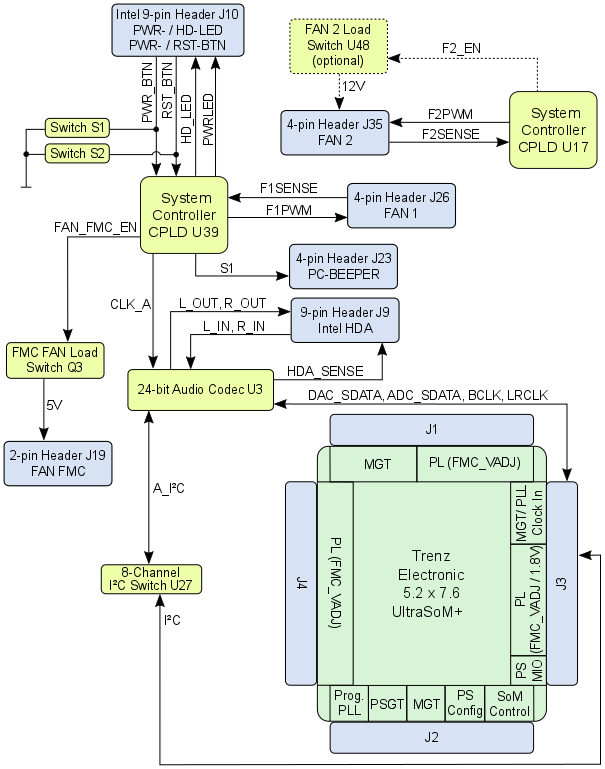

| J10 | Pin 1, HD LED+ | HD LED Anode | SC CPLD U39 | Reset und Power Switch-pins are also connected to switch buttons S1 and S2 |

| J9 | Pin 1, PORT1L | Microphone Jack Left Microphone Jack Right Audio Out Jack Left Audio Out Jack Right Jack Detect / Mic in Ground | 24-bit Audio Codec IC U3 | - |

| J23 | Pin 1, 3V3SB Pin 4, S1 | 3.3V DC Supply PC compatible Beeper | SC CPLD U39 | - |

| J26 | Pin 1, GND | Ground 12V DC Supply RPM PWM | SC CPLD U39 | 4-wire PWM FAN connector |

| J35 | Pin 1, GND | Ground 12V DC Supply RPM PWM | SC CPLD U39 | 4-wire PWM FAN connector |

| J19 | Pin 1, GND | Ground 5V DC Supply | Load Switch Q3 (5V DCDC) | 2-wire FAN connector Fan off/on switchable by signal 'FAN_FMC_EN' on SC CPLD U39 |

Table 8: PC compatible Headers

Figure 7: TEBF0808 PC Compatible Headers

...

Further JTAG interfaces of the TEBF0808 carrier board are the ARM JTAG 20-pin IDC connector J30 and on the FMC Connector J5. This JTAG interfaces are connected to the System Controller CPLD U17, hence the logical processing and forwarding of the JTAG signals depend on the SC CPLD firmware. The documentation of the firmware of the SC CPLD U17 contains detailed information on this matter.

On-board Peripherals

System Controller CPDLs

The TEBF0808 is equipped with two System Controller CPLDs with the schematic designators U17 and U39. The CPLDs are provided by Lattice Semiconductor LCMXO2-1200HC (MachXO2 Product Family).

The SC-CPLD is the central system management unit where essential control signals are logically linked by the implemented logic in CPLD firmware, which generates output signals to control the system, the on-board peripherals and the interfaces. Interfaces like JTAG and I2C between the on-board peripherals and to the FPGA-module are by-passed, forwarded and controlled by the System Controller CPLD.

Other tasks of the System Controller CPLD are the monitoring of the power-on sequence and to display the programming state of the FPGA module.

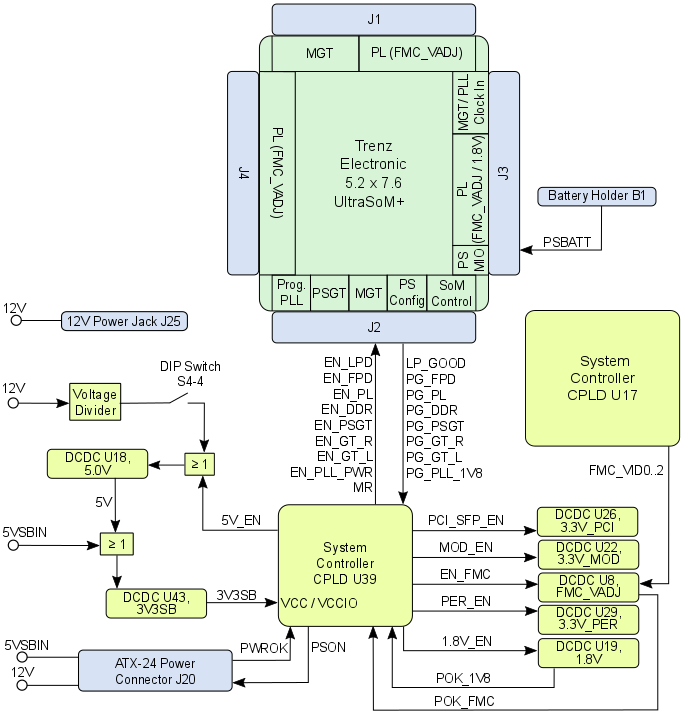

Power and Power-up Sequence

Boot Process

TE0745 module supports different boot modes which are configurable by the control line 'BOOTMODE' and 'BOOTMODE_1'. The line 'BOOTMODE' is available on B2B connector pin J2-133, the line 'BOOTMODE_1' is connected to the System Controller CPLD on bank 1, pin 21.

The current boot mode will be set by the MIO pins MIO3...MIO5. The control line 'BOOTMODE' is connected to the 'MIO4' pin, 'BOOTMODE_1' to 'MIO5'.

Following table describes how to set the control lines to configure the desired boot mode:

| Boot Mode | MIO5 (BOOTMODE_1) | MIO4 (BOOTMODE) | MIO3 | Note |

|---|---|---|---|---|

JTAG | 0 | 0 | 0 | - |

| NOR | 0 | 0 | 1 | MIO3 pin is shared with QSPI Flash Memory (QSPI-DQ1) |

| NAND | 0 | 1 | 0 | - |

| QSPI Flash Memory | 1 | 0 | 0 | standard mode in current configuration |

| SD-Card | 1 | 1 | 0 | SD-Card on base board necessary |

Table 11: Selectable boot modes

In delivery state of the SoM the boot mode depends on the configured SC-CPLD firmware. The current mode is set to boot from the QSPI Flash Memory.

On-board Peripherals

System Controller CPDLs

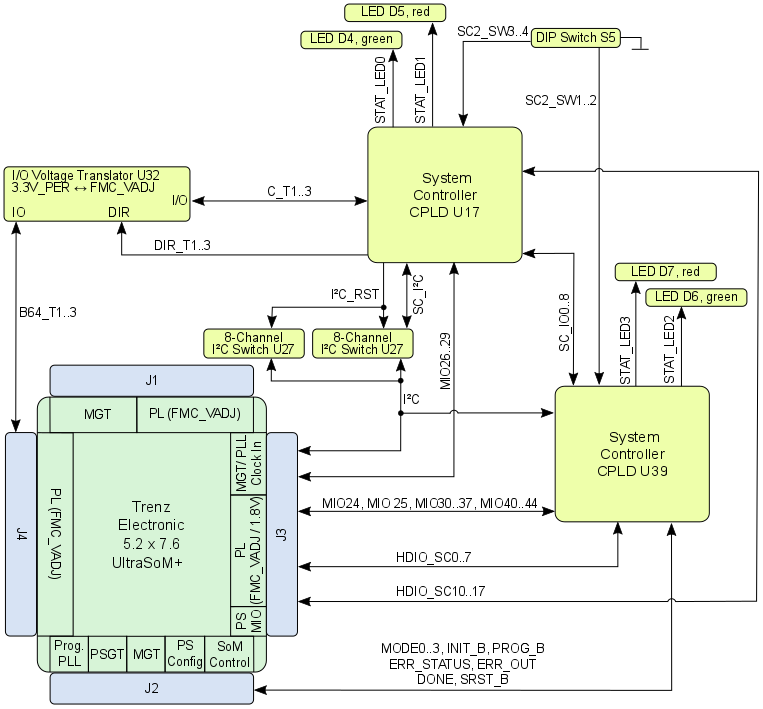

The TEBF0808 is equipped with two System Controller CPLDs - Lattice Semiconductor LCMXO2-1200HC (MachXO2 Product Family) - with the schematic designators U17 and U39.

The SC-CPLD is the central system management unit where essential control signals are logically linked by the implemented logic in CPLD firmware, which generates output signals to control the system, the on-board peripherals and the interfaces. Interfaces like JTAG and I2C between the on-board peripherals and to the FPGA-module are by-passed, forwarded and controlled by the System Controller CPLD.

Other tasks of the System Controller CPLD are the monitoring of the power-on sequence and to display the programming state of the FPGA module.

Both Sytem Controller CPLDs are connected to the Zynq Ultrascale+ MPSoC through MIO and also Programmable Logic pins.

The functionalities and configuration of the pins depend on the CPLDs' firmware. The documentations of the firmware of SC CPLD U17 and SC CPLD U39 contains detailed information on this matter.

Following block diagram visualizes the connection of the SC CPLDs with the Zynq Ultrascale+ MPSoC via PS (MIO) and PL bank pins.

Figure 8: TEBF0808 System Controller CPLDs

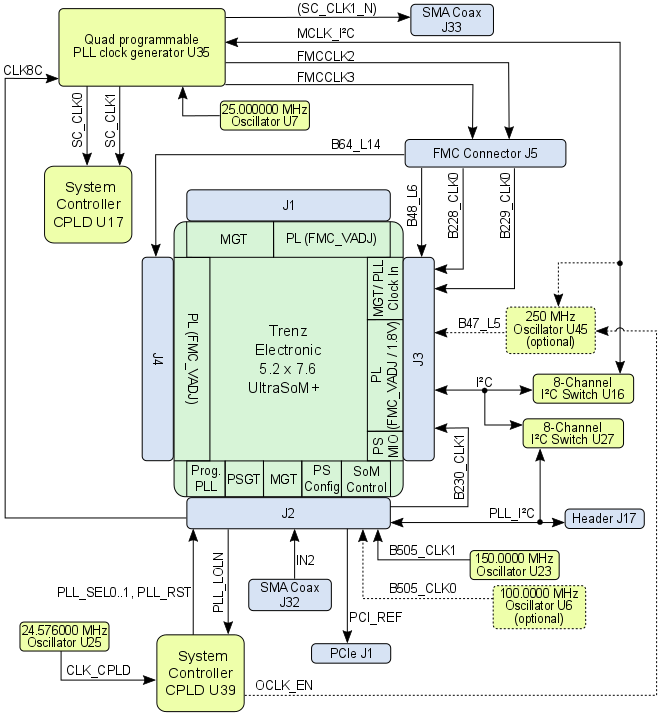

Programmable PLL Clock Generator and Reference Clock Oscillators

The TEBF0808 Carrier Board is equipped with a Silicon Labs I2C programmable quad PLL clock generator Si5338A (U35). It's output frequencies can be programmed by using the I2C bus with address 0x70.

A 25 MHz (U7) oscillator is connected to pin 3 (IN3) and is used to generate the output clocks.

Once running, the frequency and other parameters can be changed by programming the device using the I2C-bus connected through I²C switch U16 between the Zynq module (master) and reference clock signal generator (slave).

| Si5338A (U13) Input | Signal Schematic Name | Note |

|---|---|---|

IN1/IN2 | CLK8_P, CLK8_N | Reference clock signal from Si5345 (CLK8 of prog. PLL on mounted SoM) |

IN3 | reference clock signal from oscillator SiTime SiT8008BI (U7) | 25.000000 MHz fixed frequency. |

IN4/IN6 | pins put to GND | LSB (pin 'IN4') of the default I²C-adress 0x70 not activated. |

IN5 | not connected | - |

| Si5338A (U13) Output | Signal Schematic Name | Note |

CLK0 A/B | SC_CLK0 | Reference clock signal to SC CPLD U17 (single-ended signaling) |

CLK1 A/B | SC_CLK1 | Reference clock signal to SC CPLD U17 (single-ended signaling) |

CLK2 A/B | FMCCLK2_P, FMCCLK2_N | Clock signal routed to FMC connector J5, pins J5-K4 / J5-K5 |

| CLK3 A/B | FMCCLK3_P, FMCCLK3_N | Clock signal routed to FMC connector J5, pins J5-J2 / J5-J3 |

Table 9: Pin description of PLL clock generator Si5338A

Figure 8: Clocking Configuration of TE0808 SoM on TEBF0808 Carrier Board

To configure the programmable PLL clock generator on the mounted TE0808 SoM, refer to the TRM of this SoM.

| Note |

|---|

Si5338 OTP ROM is not programmed by default at delivery, so it is customers responsibility to either configure Si5338 during FSBL or then use SiLabs programmer and burn the OTP ROM with customer fixed clock setup. |

Si5345 OTP can only be programmed two times, as different user configurations may required different setup, TEBF0808 is normally shipped with blank OTP.

For more information Si5338 at SiLabs.

Oscillators

The TEBF0808 carrier board is equipped several on-board oscillators to provide the Zynq Ultrascale+ MPSoC's PS and PL banks and the on-board peripherals with reference clock-signals:

| Clock Source | Schematic Name | Frequency | Clock Input Destination |

|---|---|---|---|

| SiTime SiT8008BI oscillator, U21 | - | 25.000000 MHz | Quad PLL clock generator U16, pin 3 |

SiTime SiT8008BI oscillator, U12 | PS_CLK | 33.333333 MHz | Bank 500 (MIO0 bank), pin B24 |

| SiTime SiT8008BI oscillator, U33 | OTG-RCLK | 52.000000 MHz | USB 2.0 transceiver PHY U32, pin 26 |

| SiTime SiT8008BI oscillator, U9 | ETH_CLKIN | 25.000000 MHz | Gigabit Ethernet PHY U7, pin 34 |

Table 10: Reference clock signal oscillators

High-speed USB ULPI PHY

USB PHY (U32) is provided by USB3320 from Microchip. The ULPI interface is connected to the Zynq PS USB0. I/O voltage is fixed at 1.8V and PHY reference clock input is supplied from the on-board 52.000000 MHz oscillator (U33).

| PHY Pin | ZYNQ Pin | B2B Name | Notes |

|---|---|---|---|

| ULPI | MIO28 ... MIO39 | - | Zynq USB0 MIO pins are connected to the PHY. |

| REFCLK | - | - | 52MHz from on board oscillator (U33). |

| REFSEL[0..2] | - | - | All pins set to GND selects the external reference clock frequency (52.000000 MHz). |

| RESETB | MIO7 | - | Low active USB PHY Reset (pulled-up to PS_1.8V). |

| CLKOUT | MIO36 | - | Set to logic high to select reference clock (oscillator U33) operation mode. |

| DP, DM | - | OTG_D_P, OTG_D_N, pin J2-149 / J2-151 | USB data lines. |

| CPEN | - | VBUS_V_EN, pin J2-141 | External USB power switch active-high enable signal. |

| VBUS | - | USB_VBUS, pin J2-145 | Connect to USB VBUS via a series of resistors, see reference schematics. |

| ID | - | OTG_ID, pin J2-143 | For an A-device connect to the ground. For a B-device, leave floating. |

Table 8: USB PHY interface connections

The schematics for the USB connector and required components is different depending on the USB usage. USB standard A or B connectors can be used for Host or Device modes. A Mini USB connector can be used for USB Device mode. A USB Micro connector can be used for Device mode, OTG Mode or Host Mode.

Gigabit Ethernet PHY

On-board Gigabit Ethernet PHY (U7) is provided with Marvell Alaska 88E1512 IC. The Ethernet PHY RGMII interface is connected to the Zynq Ethernet0 PS GEM0. I/O voltage is fixed at 1.8V for HSTL signaling. The reference clock input of the PHY is supplied from the on-board 25.000000 MHz oscillator (U9). The 125MHz PHY output clock (PHY_CLK125M) is routed to the B2B connector J2 pin 150.

| PHY Pin | ZYNQ PS | B2B | Notes |

|---|---|---|---|

| MDC/MDIO | MIO52, MIO53 | - | - |

| PHY LEDs | - | PHY_LED0: J2-144 | - |

| PHY_LED2 / INTn: | - | J2-148 | Active low interrupt line |

| PHY_CLK125M | - | J2-150 | 125 MHz Ethernet PHY clock out |

| CONFIG | - | - | Permanent logic high |

| RESETn | MIO9 | - | Active low reset line |

| RGMII | MIO16 ... MIO27 | - | Reduced Gigabit Media Independent Interface |

| SGMII | - | - | Serial Gigabit Media Independent Interface |

| MDI | - | PHY_MDI0: J2-120 / J2-122 PHY_MDI1: J2-126 / J2-128 PHY_MDI2: J2-132 / J2-134 PHY_MDI3: J2-138 / J2-140 | Media Dependent Interface |

Table 7: Ethernet PHY interface connections

I2C Switches

The I2C interface on B2B connector J2 pins 119 (I2C_33_SCL) and 121 (I2C_33_SDA) have PS_3.3V as reference voltage.

The I2C bus works internally on module with reference voltage 1.8V, on the Zynq chip it is connected to the PS I2C interface via PS MIO bank 500, pins MIO10 and MIO11.

| MIO | Signal Schematic Name | Notes |

|---|---|---|

| 10 | I2C_SCL | 1.8V reference voltage |

| 11 | I2C_SDA | 1.8V reference voltage |

Table 9: MIO-pin assignment of the module's I2C interface

Except the RTC (U24), all I2C slave devices are operating with the reference voltage PS_1.8V via voltage level translating (3.3V ↔ 1.8V) I2C bus repeater (U17).

I2C addresses for on-board devices are listed in the table below:

| I2C Device | I2C Address | Notes |

|---|---|---|

| Zynq chip U1, bank 500 (PS MIO), pins MIO10 (SCL), MIO11 (SDA) | User programmable | Configured as I2C by default |

| Quad programmable PLL clock generator U16: pins 12 (SCL), 19 (SDA) | 0x70 | - |

| MAC Address EEPROM U23, pins 1 (SCL), 3 (SDA) | 0x53 | - |

| SC CPLD U2, bank 2, pins 16 (SDA), 17 (SCL) | User programmable | - |

| RTC, U24 | 0x6F | - |

| RTC RAM, U24 | 0x57 | - |

Table 10: Module's I2C-interfaces overview

System Controller CPLD

The System Controller CPLD (U2) is provided by Lattice Semiconductor LCMXO2-256HC (MachXO2 Product Family). The SC-CPLD is the central system management unit where essential control signals are logically linked by the implemented logic in CPLD firmware, which generates output signals to control the system, the on-board peripherals and the interfaces. Interfaces like JTAG and I2C between the on-board peripherals and to the FPGA-module are by-passed, forwarded and controlled by the System Controller CPLD.

Other tasks of the System Controller CPLD are the monitoring of the power-on sequence and to display the programming state of the FPGA module.

Quad SPI Flash Memory

On-board QSPI flash memory (U14) on the TE0745-02 is provided by Micron Serial NOR Flash Memory N25Q256A with 256 Mbit (32 MByte) storage capacity. This non volatile memory is used to store initial FPGA configuration. Besides FPGA configuration, remaining free flash memory can be used for user application and data storage. All four SPI data lines are connected to the FPGA allowing x1, x2 or x4 data bus widths. Maximum data rate depends on the selected bus width and clock frequency used.

| Note |

|---|

SPI Flash QE (Quad Enable) bit must be set to high or FPGA is unable to load its configuration from flash during power-on. By default this bit is set to high at the manufacturing plant. |

Gigabit Ethernet PHY

On-board Gigabit Ethernet PHY (U7) is provided with Marvell Alaska 88E1512 IC (U8). The Ethernet PHY RGMII interface is connected to the Zynq Ethernet0 PS GEM0. I/O voltage is fixed at 1.8V for HSTL signaling. The reference clock input of the PHY is supplied from an on-board 25.000000 MHz oscillator (U9), the 125MHz output clock signal CLK_125MHZ is connected to the pin J2-150 of B2B connector J2.

High-speed USB ULPI PHY

Hi-speed USB ULPI PHY (U32) is provided with USB3320 from Microchip. The ULPI interface is connected to the Zynq PS USB0 via MIO28..39, bank 501 (see also section). The I/O voltage is fixed at 1.8V and PHY reference clock input is supplied from the on-board 52.000000 MHz oscillator (U33).

MAC Address EEPROM

A Microchip 24AA025E48 serial EEPROM (U23) contains a globally unique 48-bit node address, which is compatible with EUI-48(TM) specification. The device is organized as two blocks of 128 x 8-bit memory. One of the blocks stores the 48-bit node address and is write protected, the other block is available for application use. It is accessible over I2C bus with slave device address 0x53.

RTC - Real Time Clock

An temperature compensated Intersil ISL12020M is used as Real Time Clock (U24). Battery voltage must be supplied to the clock from the base board via pin 'VBAT_IN' (J1-146). Battery backed registers can be accessed over I2C bus at slave address 0x6F. General purpose RAM of the RTC can be accessed at I2C slave address 0x57. RTC IC is supported by Linux so it can be used as hwclock device. The interrupt line 'RTC_INT' of the RTC is connected to System Controller CPLD bank 3 pin 4.

On-board LEDs

LED | Color | Connected to | Description and Notes |

|---|---|---|---|

| D1 | red | DONE signal (PS Configuration Bank 503) | This LED goes ON when power has been applied to the module and stays ON until MPSoC's programmable logic is configured properly. |

Table 14: LED's description

Power and Power-On Sequence

Power Consumption

The maximum power consumption of a module mainly depends on the design which is running on the FPGA.

Xilinx provide a power estimator excel sheets to calculate power consumption. It's also possible to evaluate the power consumption of the developed design with Vivado. See also Trenz Electronic Wiki FAQ.

| Power Input Pin | Typical Current |

|---|---|

| DCDCIN | TBD* |

| LP_DCDC | TBD* |

| PL_DCIN | TBD* |

| PS_BATT | TBD* |

Table 15: Maximum current of power supplies. *to be determined soon with reference design setup.

Power supply with minimum current capability of 3A for system startup is recommended. For the lowest power consumption and highest efficiency of on board DC/DC regulators it is recommended to powering the module from one single 3.3V supply. Except 'PS_BATT', all input power supplies have a nominal value of 3.3V. Although the input power supplies can be powered up in any order, it is recommended to power them up simultaneously.

The TE0808 module equipped with the Xilinx Zynq Ultrascale+ MPSoC delivers a heterogeneous multi-processing system with integrated programmable logic and independently operable elements and is designed to meet embedded system power management requirement by advanced power management features. This features allow to offset the power and heat constraints against overall performance and operational efficiency.

This features allowing highly flexible power management are achieved by establishing Power Domains for power isolation. The Zynq Ultrascale+ MPSoC has multiple power domains, whereby each power domain requires its own particular extern DCDC converters.

The Processing System contains three Power Domains:

- Battery Power Domain (BBRAM and RTC)

- Full-Power Domain (Application Processing Unit, DDR Controller, Graphics Processing Unit and High-Speed Connectivity)

- Low-Power Domain (Real-Time Processing Unit, Security and Configuration Unit, Platform Management Unit, System Monitor and General Connectivity)

The fourth Power Domain is for the Programmable Logic (PL). If individual Power Domain control is not required, power rails can be shared between domains.

On the TE0808-04 SoM, following Power Domains can be powered up individually with power rails available on the B2B connectors:

- Full-Power Domain, supplied by power rail 'DCDCIN'

- Low-Power Domain, supplied by power rail 'LP_DCDC'

- Programmable Logic, supplied by power rail 'PL_DCIN'

- Battery Power Domain, supplied by power rail 'PS_BATT'

Each Power Domain has its own "Enabling"- and "Power Good"-signals. The power rail 'GT_DCDC' is necessary for generating the voltages for the Multi Gigabit Transceiver units of the Zynq Ultrascale+ MPSoC.

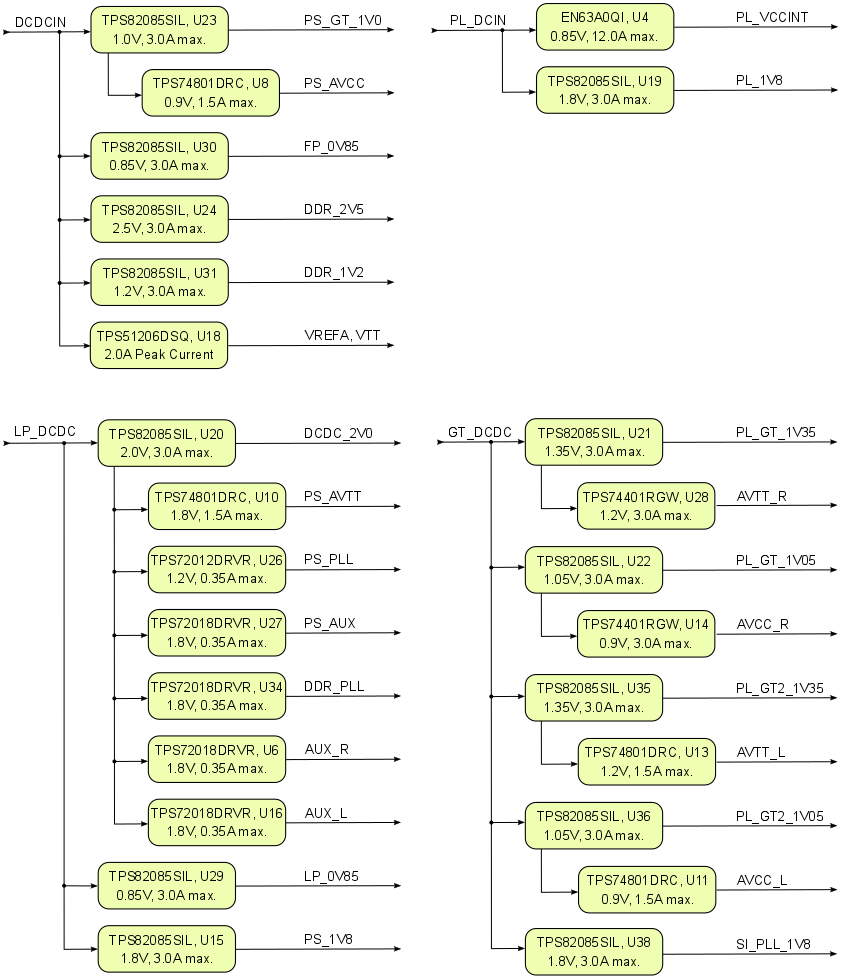

Power Distribution Dependencies

The power rails 'DCDCIN', 'LP_DCDC', 'PL_DCIN', 'PS_BATT' have to be powered up on the assigned pins of the B2B connectors as listed on the section "Power Rails". Except 'PS_BATT' (see section "Recommended Operation Conditions"), all power-rails can be powered up, with 3.3V power sources, also shared, if Power Domain control is not required.

There are following dependencies how the initial voltages of the power rails on the B2B connectors are distributed to the on-board DCDC converters, which power up further DCDC converters and the particular on-board voltages:

Figure 3: Power Distribution Diagram

| Note |

|---|

Current rating of Samtec Razor Beam™ LSHM B2B connectors is 2.0A per pin (2 adjacent pins powered). |

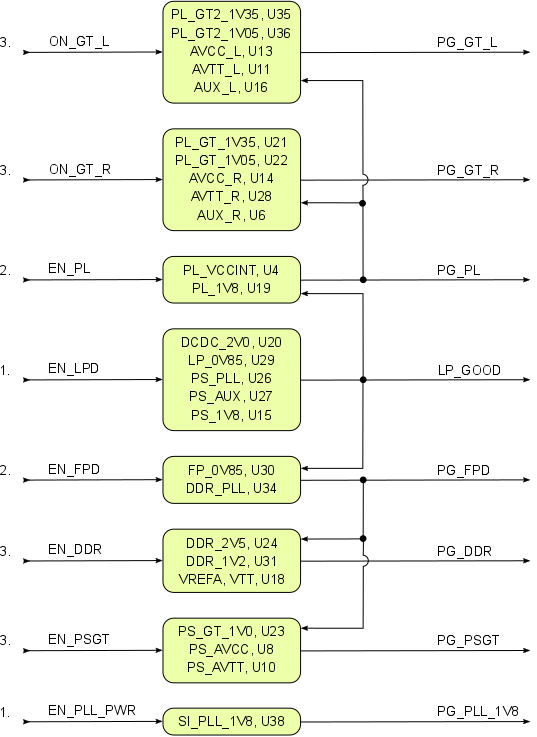

Power-On Sequence Diagram

The TE0808 SoM meets the recommended criteria to power up the Xilinx Zynq Ultrascale+ MPSoC properly by keeping a specific sequence of enabling the on-board DCDC converters dedicated to the particular Power Domains and powering up the on-board voltages.

The on-board voltages of the TE0808 SoM will be powered-up in order of a determined sequence by activating the above-mentioned power rails and the Enable-Signals of the DCDC converters. The on-board voltages will be powered up at three steps.

- Low-Power Domain (LPD) and on-board Si5345A programmable clock generator supply voltage

- Programmable Logic (PL) and Full-Power Domain (FPD)

- GTH, PS GTR transceiver and DDR memory

Hence, those three power instances will be powered up consecutively and the Power-Good-Signals of the previous instance has to be asserted.

Following diagram clarifies the sequence of enabling the three power instances utilizing the DCDC converter control signals ('Enable', 'Power-Good'), which will power-up in descending order as listed in the blocks of the diagram.

Figure 4: Power-On Sequence Utilizing DCDC Converter Control Signals

| Warning |

|---|

| To avoid any damages to the MPSoC module, check for stabilized on-board voltages in steady state before powering up the MPSoC's I/O bank voltages VCCOx. All I/O's should be tri-stated during power-on sequence. |

Core voltages and main supply voltages have to reach stable state and their "Power Good"-signals have to be asserted before other voltages like bank's I/O voltages (VCCOx) can be powered up.

It is important that all PS and PL I/Os are tri-stated at power-on until the "Power Good"-signals are high, meaning that all on-module voltages have become stable and module is properly powered up.

See Xilinx datasheet DS925 for additional information. User should also check related base board documentation when intending base board design for TE0808 SoM.

Power Rails

Voltages on B2B | B2B J1 Pin | B2B J2 Pin | B2B J3 Pin | B2B J4 Pin | Input/ | Note |

|---|---|---|---|---|---|---|

| PL_DCIN | J1-151, J1-153, J1-157, J1-159 | - | - | - | Input | - |

| DCDCIN | - | J2-154, J2-156, J2-158, J2-160, | - | - | Input | - |

| LP_DCDC | - | J2-138, J2-140, J2-142, J2-144 | - | - | Input | - |

| PS_BATT | - | J2-125 | - | - | Input | - |

| GT_DCDC | - | - | J3-157, J3-158, J3-159, J3-160 | - | Input | - |

| PLL_3V3 | - | - | J3-152 | - | Input | U5 (programmable PLL) 3.3V nominal input |

| SI_PLL_1V8 | - | - | J3-151 | - | Output | Internal voltage level 1.8V nominal output |

| PS_1V8 | - | J2-99 | J3-148 | - | Output | Internal voltage level |

| PL_1V8 | J1-91, J1-121 | - | - | - | Output | Internal voltage level |

| DDR_1V2 | - | J2-135 | - | - | Output | Internal voltage level |

Table 17: Power rails of the MPSoC module on accessible connectors

Bank Voltages

| Bank | Type | Schematic Name / B2B connector Pins | Voltage | Reference Input Voltage | Voltage Range |

|---|---|---|---|---|---|

| 47 | HD | VCCO47, pins J3-43, J3-44 | user | - | max. 3.3V |

| 48 | HD | VCCO48, pins J3-15, J3-16 | user | - | max. 3.3V |

| 64 | HP | VCCO64, J4-58, J4-106 | user | VREF_64, pin J4-88 | max. 1.8V |

| 65 | HP | VCCO65, J4-69, J4-105 | user | VREF_65, pin J4-15 | max. 1.8V |

| 66 | HP | VCCO66, J1-90, J1-120 | user | VREF_66, pin J1-108 | max. 1.8V |

| 500 | MIO | PS_1V8 | 1.8V | - | - |

| 501 | MIO | PS_1V8 | 1.8V | - | - |

| 502 | MIO | PS_1V8 | 1.8V | - | - |

| 503 | CONFIG | PS_1V8 | 1.8V | - | - |

Table 18: Range of MPSoC module's bank voltages

B2B connectors

| Include Page | ||||

|---|---|---|---|---|

|

Technical Specifications

Absolute Maximum Ratings

Parameter | Min | Max | Unit | Notes / Reference Document |

|---|---|---|---|---|

| PL_DCIN | -0.3 | 7 | V | TPS82085SIL / EN63A0QI data sheet |

| DCDCIN | -0.3 | 7 | V | TPS82085SIL / TPS51206 data sheet |

| LP_DCDC | -0.3 | 4 | V | TPS3106K33DBVR data sheet |

| GT_DCDC | -0.3 | 7 | V | TPS82085SIL data sheet |

| PS_BATT | -0.5 | 2 | V | Xilinx DS925 data sheet |

| PLL_3V3 | -0.5 | 3.8 | V | Si5345/44/42 data sheet |

| VCCO for HD I/O banks | -0.5 | 3.4 | V | Xilinx DS925 data sheet |

| VCCO for HP I/O banks | -0.5 | 2 | V | Xilinx DS925 data sheet |

| VREF | -0.5 | 2 | V | Xilinx DS925 data sheet |

| I/O input voltage for HD I/O banks | -0.55 | VCCO + 0.55 | V | Xilinx DS925 data sheet |

| I/O input voltage for HP I/O banks | -0.55 | VCCO + 0.55 | V | Xilinx DS925 data sheet |

| PS I/O input voltage (MIO pins) | -0.5 | VCCO_PSIO + 0.55 | V | Xilinx DS925 data sheet, VCCO_PSIO 1.8V nominally |

Receiver (RXP/RXN) and transmitter | -0.5 | 1.2 | V | Xilinx DS925 data sheet |

Voltage on input pins of | -0.5 | VCC + 0.5 | V | NC7S08P5X data sheet, see schematic for VCC |

Voltage on input pins (nMR) of | -0.3 | VDD + 0.3 | V | TPS3106 data sheet, |

| "Enable"-signals on TPS82085SIL ('EN_PLL_PWR', 'EN_LPD') | -0.3 | 7 | V | TPS82085SIL data sheet |

Storage temperature (ambient) | -40 | 100 | °C | ROHM Semiconductor SML-P11 Series data sheet |

| Note |

|---|

| Assembly variants for higher storage temperature range are available on request. |

Recommended Operating Conditions

| Parameter | Min | Max | Unit | Notes / Reference Document |

|---|---|---|---|---|

| PL_DCIN | 2.5 | 6 | V | EN63A0QI / TPS82085SIL data sheet |

| DCDCIN | 3.1 | 6 | V | TPS82085SIL / TPS51206PSQ data sheet |

| LP_DCDC | 2.5 | 3.6 | V | TPS82085SIL / TPS3106 data sheet |

| GT_DCDC | 2.5 | 6 | V | TPS82085SIL data sheet |

| PS_BATT | 1.2 | 1.5 | V | Xilinx DS925 data sheet |

| PLL_3V3 | 3.14 | 3.47 | V | Si5345/44/42 data sheet 3.3V typical |

| VCCO for HD I/O banks | 1.14 | 3.4 | V | Xilinx DS925 data sheet |

| VCCO for HP I/O banks | 0.95 | 1.9 | V | Xilinx DS925 data sheet |

| I/O input voltage for HD I/O banks. | -0.2 | VCCO + 0.2 | V | Xilinx DS925 data sheet |

| I/O input voltage for HP I/O banks | -0.2 | VCCO + 0.2 | V | Xilinx DS925 data sheet |

| PS I/O input voltage (MIO pins) | -0.2 | VCCO_PSIO + 0.2 | V | Xilinx DS925 data sheet, VCCO_PSIO 1.8V nominally |

| Voltage on input pins of NC7S08P5X 2-Input AND Gate | 0 | VCC | V | NC7S08P5X data sheet, |

Voltage on input pin 'MR' of | 0 | VDD | V | TPS3106 data sheet, |

| Note |

|---|

| Please check Xilinx datasheet DS925 for complete list of absolute maximum and recommended operating ratings. |

Operating Temperature Ranges

Commercial grade: 0°C to +70°C.

Industrial grade: -40°C to +85°C.

Extended grade: 0°C to +85°C.

The module operating temperature range depends also on customer design and cooling solution. Please contact us for options.

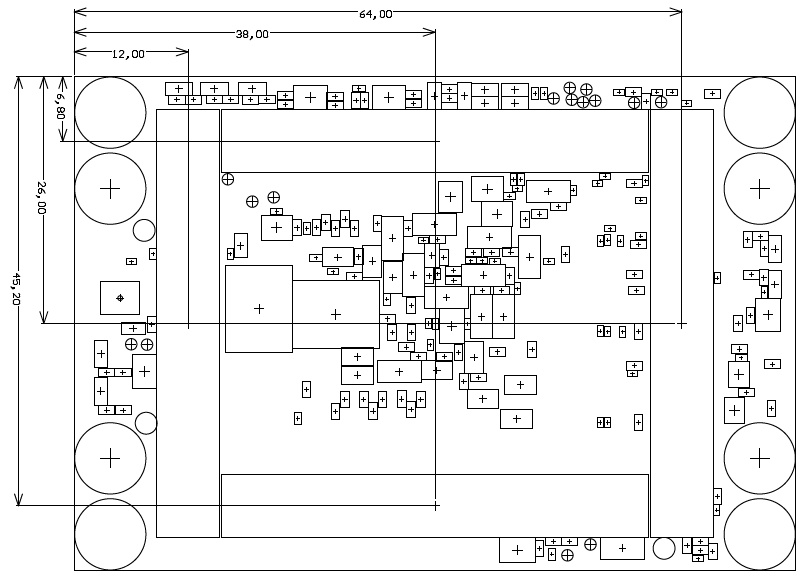

Physical Dimensions

Module size: 52 mm × 76 mm. Please download the assembly diagram for exact numbers

Mating height with standard connectors: 4mm

PCB thickness: 1.6mm

Highest part on PCB: approx. 3mm. Please download the step model for exact numbers

All dimensions are given in millimeters.

Revision History

Hardware Revision History

| Date | Revision | Notes | Link to PCN | Documentation Link |

|---|---|---|---|---|

| - | 04 | First production silicon | - | - |

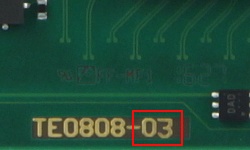

| - | 03 | Second ES production release | - | TE0808-03 |

| 2016-03-09 | 02 | First ES production release | - | TE0808-02 |

| - | 01 | Prototypes | - | - |

Hardware revision number is written on the PCB board together with the module model number separated by the dash.

Document Change History

| Date | Revision | Contributors | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| John Hartfiel, Ali Naseri |

| |||||||||

| 2017-02-06 | V1 | Jan Kumann | Initial document |

Disclaimer

| Include Page | ||||

|---|---|---|---|---|

|